- Industrial machines and equipment >

- Furnace and Heat Treatments >

- Tunnel oven

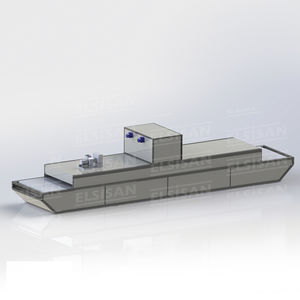

Tunnel ovens

Maximum temperature: 300 °C

Ovens with a range up to 300°C can be supplied. Electric or gas operation with efficient and optimized design.

... capacity. Heating of the tunnel type oven conducted by electricity or natural gas. All electrical equipment controlled by PLC. Belt speed sets by the inverter to drying the material in the desired quality. ...

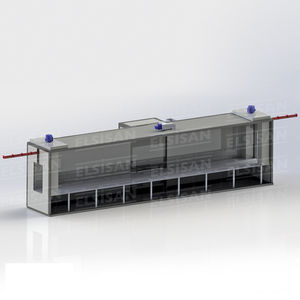

Elsisan

U type ovens are designed according to the process and the layout of the facility. The material lined up on the conveyor enter and exit on the same surface of the oven. They save energy thanks to their ...

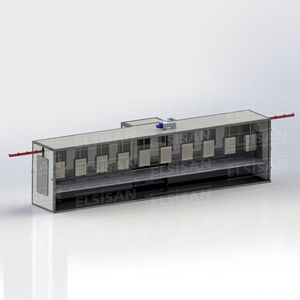

Elsisan

These ovens are used in liquid and powder paint applications. It is used for curing large parts, especially when the paint application takes a long time. The materials that move step by step on the conveyor, go to the ...

Elsisan

Width: 20 cm

Height: 10 cm

Compact IR Compact IR Tunnel perfect to complement any conventional inkjet printing process to speed up drying. Features: 200 mm web width x 1000 mm length. Adjustable Mouth Height from 0 to 150 mm Metal or ...

TODO IMPRESIÓN SYSTEMS, SL

Maximum temperature: max 250.0 °C

Width: max 80.0 cm

Height: max 10.0 cm

IR Tunnel Conventional IR Tunnel available in a wide range of sizes and powers perfect to complement any conventional ink printing process to accelerate drying or high temperature curing. Features: Web ...

TODO IMPRESIÓN SYSTEMS, SL

Compact UV UV tunnel for small products, can be manufactured in flat version or for products requiring vertical curing. Available with Medium Pressure lamps or LED technology. Quality: Designed for industry ...

TODO IMPRESIÓN SYSTEMS, SL

Maximum temperature: 1,000 °C

Width: 200 mm

Height: 200 mm

... Resistant Muffle Furnace product is suitable for heat treatment of various samples in the laboratory, including those with corrosive effect,The material of the furnace chamber is a high alumina poly-light ...

Henan Sante Furnace Technology Co.,Ltd.

Maximum temperature: 1,200 °C

Width: 450 mm

Height: 600 mm

... Features Furnace Shell The shell is made of metal Q235 low-carbon steel, and the surface is electrostatically resistant and anti-corrosion. Strong metal frame shell structure, low furnace surface ...

Henan Sante Furnace Technology Co.,Ltd.

Maximum temperature: 1,200 °C

Width: 300 mm

Height: 300 mm

... Features Furnace Shell The shell is made of metal Q235 low-carbon steel, and the surface is electrostatically resistant and anti-corrosion. Strong metal frame shell structure, low furnace surface ...

Henan Sante Furnace Technology Co.,Ltd.

Maximum temperature: 0 °C - 1,200 °C

Width: 650, 800, 950 cm

Height: 635, 675 cm

... tube furnaces are multi-zone furnaces that could be used when laboratory experimentation is performed horizontally, vertically, or at specific angles. Configuration of the tilt angle, and the stable ...

Protherm Furnaces

Height: 1,700 mm

Depth: 1,350 mm

High-Speed and High-Power! Conveyor Type Suitable for Mass Production. * Fish fillet can be cooked for 4 minutes. It is possible to cook more than 4000 pieces of fish fillets per 1 hour. * Food factory, facility in which school lunch ...

The GRT 30/40 fully automated varnish-coating machine is specifically engineered for continuously conducted operations of varnish laying on work-pieces. The machine comprises an external enclosure whose walls and top are manufactured ...

Maximum temperature: 1,150 °C

Capacity: 9 l - 87 l

Width: 800, 1,040 mm

... heat-treating metals, robust insulation with light refractory bricks is necessary. The chamber furnaces N 7/H - N 87/H are a perfect fit to solve this problem. The furnaces can be extended with a variety ...

Maximum temperature: 100, 140 °C

Width: 1,500, 870 mm

Height: 1,150, 460 mm

The application area of Conveyor Ovens is versatile. Conveyor Ovens are suitable for continuous heating, thermal treatment or clock-controlled dwell times of components. Applicable are single parts on ...

Maximum temperature: 1,000 °C

It is a kiln for burning various materials such as the anode and cathode materials for rechargeable batteries, the high-precision temperature control, optimized air supply and exhaust system, and stable operation are ...

Maximum temperature: 90, 100, 150, 300 °C

... architectures for you continuous heat treatment tunnel will allow adaptation to your installation constraints. Solid or mesh type conveyor belt Conveyor with braced chains or rollers Rotary hearth furnace Alternating, ...

Width: 1,300, 1,550 mm

Height: 1,420 mm

... maintenance cycle and enables maintenance in a short time period Environmental-conscious • The internal structure of the oven is redesigned to contribute to carbon neutrality, further reducing the amount of electricity ...

Maximum temperature: 0 °C - 200 °C

As another example of an intelligent combination, PINK combines VSD vacuum drying ovens, isolators and pressure nutsches in integrated systems. This combination enables the prefiltration of liquid products before the ...

Maximum temperature: 80, 40 °C

Width: 1,000 mm

Height: 1,300 mm

Fillet Brightening Cabinet is to brighten fillets. Put 180-250kg fillets on the grid, close the door, and turn on the air pump to let redundant air out. Finally inject carbon monoxide into machine for 25-35 mins. The machine consists ...

Maximum temperature: 0 °C - 1,150 °C

Conveyor belt furnace with horizontal metal muffle fitted Heating and cooling of the workpieces under protective atmosphere High uniformity of treatment Heat-up time and conditionning atmosphere very fast Especially ...

Maximum temperature: 180 °C - 220 °C

OVERSATIL Series polymerization ovens developed by SciTeeX are designed to ensure optimum curing conditions for the powder applied to a workpieces surface, by heating it to a temperature of 180ºC to 220ºC. At ...

Maximum temperature: 200 °C

Width: 228, 208, 178, 158 cm

Oven for drying and polymerization of screen printing inks designed for use in the textile and graphic sectors. The evaporation of water and solvents is guaranteed by a forced air ventilation. Constant and adjustable ...

INDUSTRIAL DRYING The use of metal resistors with predictable thermal inertia makes it possible to generate heat with a high degree of accuracy. In addition they do not pollute their surrounding gas which may, for example, be used ...

Maximum temperature: 565 °C - 950 °C

... washing System for degreasing, dephosphating and drying •A conveyor belt that feeds the furnace loading System •A vibrating loading System for the hardening furnace that achieves uniform piece distribution ...

La Fornitecnica S.r.l.

Maximum temperature: 870 °C - 927 °C

... washing System for degreasing, dephosphating and drying •A conveyor belt that feeds the furnace loading System •A vibrating loading System for the hardening furnace that achieves uniform piece distribution ...

La Fornitecnica S.r.l.

... Nitriding The T-REX series - continuous pusher furnaces - has been developed to obtain the separation between the different carburizing phases that require different atmosphere and temperature values. The furnace ...

La Fornitecnica S.r.l.

... with final UV hardening, or otherwise fast drying for one- and/or two-components water based lacquers. Benefits Modular oven, in order to have high flexibility about drying times. Very short times for flash-off or ...

Cefla Finishing

EB/PVD SMART Coater Vacuum Turbine Blade Coating for thermal barrier coating Short campaign times Small investment costs High part flexibility Small floor space requirements/ no pit One man operation and service ...

Maximum temperature: 0 °C - 1,250 °C

ModulTherm® Vacuum heat treatment system with high pressure gas quenching ALD ModulTherm® heat treatment technology has been used successfully worldwide for many years and is the preferred method for the heat treatment of new transmissions ...

Maximum temperature: 0 °C - 300 °C

The preheating ovens at 300°C, installed at the beginning of the lines, optimize the subsequent cleaning of the pieces, and support the development of water-based paints.

Maximum temperature: 0 °C - 100 °C

... an existing oven. The compact unit preheats the weld seams just before the cans enter the oven. Accommodates faster weld lines without increasing floor space requirements Sets powder side-seam ...

Exactly kiln temperature control, low temperature difference, high heat utilization rate, good cooling effect, high speed, flat, even pore; accompany with tunnel kiln, more than 20% gas saved, and comprehensive ...

The printed front &rear contacts are fired into the PN junction layer to form an ohmic contact through firing process,which allows the electrical energy collected by the fingers to flow out through the busbars. · Dual-track production ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining