- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

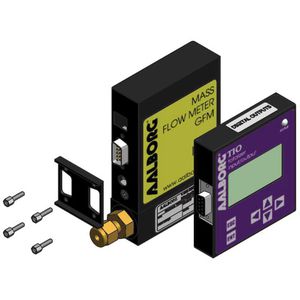

Thermal mass flow meter GFM for gasin-linestainless steel

Add to favorites

Compare this product

Characteristics

- Technology

- thermal mass

- Fluid

- for gas

- Installation

- in-line

- Material

- stainless steel, aluminum

- Communication

- 4-20 mA, analog output, digital output

- Applications

- industrial, for low flow rates, for the pharmaceutical industry, for the petrochemical industry, laboratory, for environmental analysis, for the oil and gas industry, for test benches

- Other characteristics

- precision, with LCD display, economical

- Volumetric flow rate

Min.: 0 l/min

(0 us gal/min)Max.: 1,000 l/min

(264.2 us gal/min)- Process temperature

Min.: 0 °C

(32 °F)Max.: 50 °C

(122 °F)21 °C

(70 °F)- Process pressure

Min.: 0 psi

Max.: 1,000 psi

Description

Design Features

• ± 1% FS accuracy is standard

• rigid metallic construction

• available flow ranges starting from 0 to 10 sccm up to 0 to 1000 slpm

• maximum pressure of 1000 psig (70 bars)

• leak integrity 1 x 10-9 sccs of helium

• NIST traceable certification

• built-in tiltable LCD readout (some models)

• 0-5 Vdc and 4-20 mA signals

• circuit protection

• can be used as a portable device

• engineering units or 0 to 100% displays

• totalizer option

Wide gas variety applications. Calibration based on the K- factor of a gas relative to N2

Available with PTFE/Kalrez , Viton , Buna and EPR seals

A low cost solution to thermal mass flow metering for gases is presented by Aalborg in introducing the model GFM mass flow meter line.

The GFM design combines the convenience and accuracy of conventional mass flow devices with low costs previously unattainable. Each of these meters incorporate an advanced straight tube sensor in conjunction with flow passage elements constructed of aluminum and brass for non-corrosive gases or 316 stainless steel for corrosive applications.

Principles of Operation

Metered gases are divided into two laminar flow paths, one through the primary flow conduit, and the other through a capillary sensor tube. Both flow conduits are designed to ensure laminar flows and therefore the ratio of their flow rates is constant.

Two precision temperature sensing windings on the sensor tube are heated, and when flow takes place, gas carries heat from the upstream to the downstream windings. The resultant temperature differential is proportional to the change in resistance of the sensor windings.

VIDEO

Catalogs

GFM

5 Pages

Other Aalborg Instruments products

Mass Flow Meters / Controllers

Related Searches

- Aalborg flow meter

- Aalborg liquid flow meter

- Level limit switch

- Liquid level limit switch

- Aalborg gas flow meter

- Aalborg stainless steel flow meter

- Industrial flowmeter

- Float level switch

- Aalborg in-line flow meter

- Aalborg precision flow meter

- Compact flowmeter

- Aalborg water flow meter

- Mass flowmeter

- Flowmeter with display

- Digital flowmeter

- RS485 flowmeter

- Aalborg variable-area flow meter

- Aalborg aluminum flow meter

- High-accuracy flowmeter

- Modbus flowmeter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.