- Products

- PCB buffer system

- ASYS GROUP

- Products

- Catalogs

- News & Trends

- Exhibitions

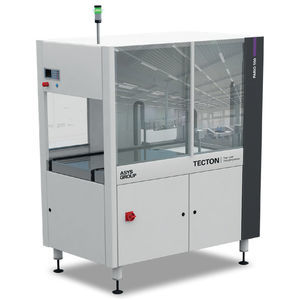

PCB buffer system VEGO BBS 20

Add to favorites

Compare this product

Description

Description

The BBS 20 buffer station consists of multiple closed conveyor segments built on top of each other for intermediate storage of up to 20 PCBs for subsequent handover to the downstream system.

Arriving PCBs are taken over onto the buffer segment and positioned. If required, the PCBs can be buffered and automatically handed over to the downstream machine using the FIFO

principle. It can be used to store PCBs after an oven, a pick and place or inspection (AOI) system for compensation of processrelated downtimes. The BBS 20 functions according to

the FIFO (First In / First Out) principle. The design of the buffer allows to handle easily PCB ́s with sidelong cut-outs

Features

_ LCD control panel

_ Product memory function

_ Operating modes:

- FIFO

- Pass-through

_ Cycle time < 25s at FIFO

_ Light tower, single stage with buzzer

_ Anti-static conveyor belts

_ SMEMA Interface

Options

_ Transport height 850 mm ± 50 mm

_ Electrical width adjustment

_ Automatic width adjustment

_ LIFO mode

_ Inlet/outlet conveyor with cover

_ Safety shutter at inlet and/or outlet

_ Cooling function with fans

_ Error loop

_ Good / Bad- sorting function

Catalogs

VEGO BBS 20

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.