- Hydraulics - Pneumatics

- Compressor

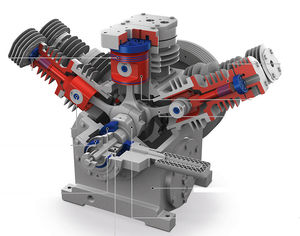

- Piston compressor

- Burckhardt Compression AG

Piston compressor H, F, Kgaselectrically-poweredstationary

Add to favorites

Compare this product

Characteristics

- Technology

- piston

- Type

- gas

- Power source

- electrically-powered

- Portability

- stationary

- Lubrication

- lubricated

- Application domain

- industrial

- Applications

- discharge

- Other characteristics

- rugged, high-pressure

- Pressure

Max.: 50,760 psi

Min.: 0 psi

- Power

Max.: 38,000 kW

(51,665.6 hp)Min.: 4,600 kW

(6,254.26 hp)

Description

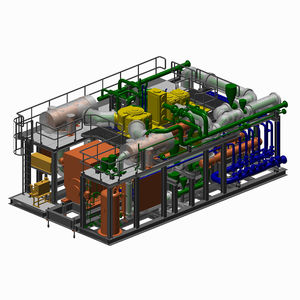

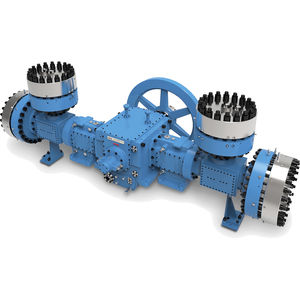

The Hyper Compressor is a high-pressure reciprocating compressor for low density polyethylene plants and compress ethylene with discharge pressure up to 3’500 bara (50’000 psia). Burckhardt Compression has an outstanding experience of over 55 years in manufacturing Hyper Compressors. They excel with long lifetime and high safety requirements thanks to its unique design features and Burckhardt Compression’s worldwide one-stop service.

The once world’s most powerful compressor, driven by a 27’500 kW (36’900 HP) electric motor and compressing 160 tons of ethylene per hour to a discharge pressure up to 3’100 bara (45’000 psia), was built by Burckhardt Compression in 2007. Since then, Burckhardt Compression was able to deliver many more projects in this performance range.

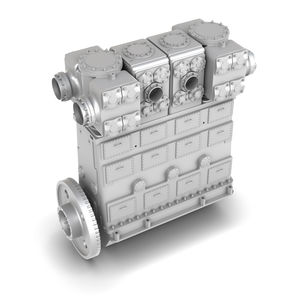

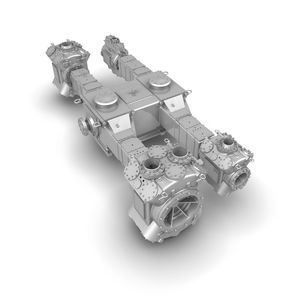

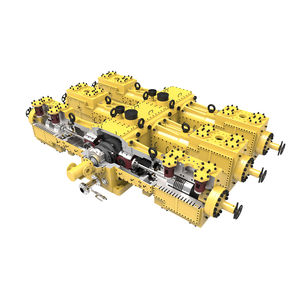

Three Different Frame Sizes

To cover the increasing demand for higher capacities in today’s LDPE plants, three different frame sizes with progressively larger cylinder diameters, longer strokes and higher admissible frame power are available. This minimizes the number of cylinders in operation for maximum availability of the client’s plant.

Significantly Lower Speed

Hyper Compressors from Burckhardt Compression are normally operating at a low nominal speed. The low nominal speed ensures minimum wear and tear of moving parts and therefore maximizes reliability and availability.

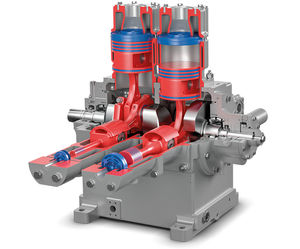

Optimized Crankcase and Crankshaft

Robust crankcase design for reliable performance

No oil sump in the crankcase

Large bearing diameters for low specific loading

Crankshaft without webs and inner holes

Rigid connecting rod for optimum pressure distribution

Crankcase lubrication system

Catalogs

Hyper Compressors

24 Pages

LABY

24 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Other Burckhardt Compression AG products

COMPRESSOR TECHNOLOGIES

Related Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Electrically-powered compressor

- Reciprocating compressor

- Oil-injected compressor

- Dry compressor

- Compact compressor

- Cooled compressor

- Tank-mounted compressor

- Gas compressor

- Air-cooled compressor

- High-pressure compressor

- Rugged compressor

- Single-stage compressor

- Water-cooled compressor

- Compressor with combustion engine

- Diesel-powered compressor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.