- Machine-tools

- Cutting Tool

- Mold milling cutter

- Dormer Pramet

- Products

- Catalogs

- News & Trends

- Exhibitions

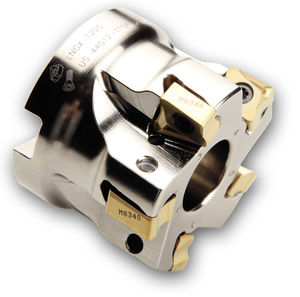

Finishing milling tool WNHX04for molds

Add to favorites

Compare this product

Characteristics

- Type

- finishing

- Other characteristics

- for molds

Description

Our family of economical milling tools includes an assortment for semi-finishing and finishing in die and mold applications.

This includes our CNHX05 double-sided inserts, with up to four cutting edges. Its unique patented wiper edges generate a high-quality surface finish, resulting in reduced machining time in both shoulder and face milling applications.

This is supported by a range of SCN05C cutters for productive copy milling of steels, hardened steels and cast irons. Available in 12mm-20mm diameters, the tool’s close pitch increases the number of teeth and enables at least 20% higher productivity than standard pitch cutters.

Meanwhile, we have launched an insert with six-cutting edges, the double-sided WNHX04 insert. This too features a unique patented wiper edge to generate superior finish on component walls and face, reducing time in cut.

This latest insert is compatible with a new range of economical and productive copy milling tools. The SWN04C cutter, available in diameters between 20-35mm, offers a variety of differential pitch options to enhance surface finish and support the six-cutting edge insert.

Designed for smooth cutting in operations with long overhang, it can be used in contouring, profiling, plunging and face milling applications with a depth of cut up to 2mm.

As with the SCN05C cutter, the SWN04C range is suitable for semi-finishing and finishing applications in steels, hardened steels and cast irons for the mold and die segment.

Catalogs

Die and mold catalog 2020

224 Pages

Pramet new products 2018

52 Pages

Pramet indexable catalog 2019

1030 Pages

Related Searches

- Milling tool

- Solid milling tool

- Steel milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Milling tool with cylindrical shank

- Metal milling tool

- Insert milling tool

- End mill milling tool

- Indexable cutting insert

- Cast iron milling tool

- General purpose drill bit

- Shell-end milling tool

- Roughing milling tool

- Face milling tool

- Carbide drilling tool

- Solid carbide milling tool

- Aluminum milling tool

- Shoulder milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.