- Machine-tools

- Machining Center

- CNC lathe

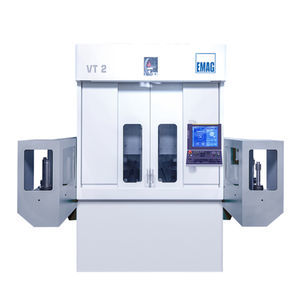

- EMAG GmbH & Co. KG

CNC turning center VSC 250vertical2-axishigh-rigidity

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Number of axes

- 2-axis

- Other characteristics

- high-speed, multi-function, high-rigidity, compact

- Diameter

315 mm, 350 mm

(12.4 in, 13.78 in)- Spindle speed

5,500 rpm

(34,557.519 rad.min-1)- Part diameter

250 mm

(10 in)- Maximum part length

175 mm

(7 in)- Axe X

745 mm

(29 in)- Axe Z

300 mm

(12 in)- Rapids on X

60,000 mm/min

(39 in/s)- Rapids on Z

30,000 mm/min

(20 in/s)- Nominal power

28 kW, 38 kW

(38.1 hp, 51.7 hp)- Maximum torque

330 Nm, 460 Nm

(243 ft.lb, 339 ft.lb)

Description

What are the advantages for the user when the main spindle of a vertical CNC lathe acts like a movable pick-up arm that collects the raw-part and unloads it again once it has been machined, carrying out all required travels, even those that have to be made during the machining process? The answer is obvious: an enormous amount of time is saved with practically every application as a number of processes are combined in one compact sequence. Of great importance for this is the heart of the CNC lathe: the multifunctional overhead slide with the pick-up spindle. This slide contains the quill that incorporates the integral workspindle and carries out all movements.

Extreme rigidity, high rapid traverse speeds and short strokes, together with the integral coolant system, guarantee precision, high productivity levels and short idle times for the VSC 250 production machine.

The VSC 250 CNC lathe is configured to suit individual manufacturing requirements incorporating vertical turning technology, integrated automation and measurement. The vertical design of the VSC 250 provides the shortest possible travel distances between the pick-up station and machining area. This reduces idle times to a minimum. The machine base of MINERALIT® and the double-wall construction ensure the best possible damping and outstanding heat stabilization. An extensive selection of technology modules allows the machine to be configured to suit individual, customer-specific production requirements.

The availability of diverse automation components also allows for integration into manufacturing systems.

Advantages

Every machine is a production cell that utilizes its pick-up spindle to load itself

VIDEO

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- 3-axis CNC machining center

- CNC turning center

- 2-axis turning center

- High-precision turning center

- Turning center with turret

- Milling machine

- 12 tools turning center

- Spindle lathe

- 3-axis turning center

- High-rigidity turning center

- Compact CNC machining center

- 3-axis milling machine

- Vertical turning center

- High-productivity turning center

- Powerful turning center

- Milling turning center

- Compact turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.