CNC turning machine VL 2vertical3-axis12 tools

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Number of axes

- 3-axis

- Number of tool stations

- 12 tools

- Other characteristics

- high-precision, with turret, spindle, Y-axis, rigid

- Diameter

160 mm

(6.3 in)- Spindle speed

6,000 rpm

(37,699.112 rad.min-1)- Part diameter

100 mm

(4 in)- Maximum part length

150 mm

(6 in)- Axe X

650 mm

(26 in)- Axe Z

375 mm

(15 in)- Rapids on X

60,000 mm/min

(39 in/s)- Rapids on Z

30,000 mm/min

(20 in/s)- Nominal power

14 kW, 18 kW

(19 hp, 24.5 hp)- Maximum torque

59 Nm, 77 Nm

(44 ft.lb, 57 ft.lb)

Description

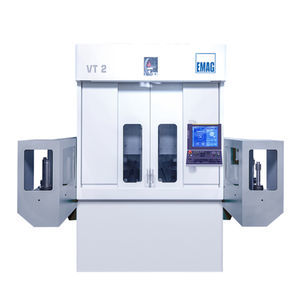

A stable machine structure, dynamic axes and ease of operation - these are the outstanding features of the VL series vertical turning machines. Based on a completely new modular machine concept, VL 2 vertical lathes make it possible to utilize various production technologies for soft and hard machining with integrated automation and a pick-up spindle, all while providing the best value for the investment.

Three axes + turret with up to twelve driven tools + automation.

The basic VL 2 machine, a three-axis inverted vertical turning machine, has an eye-catching design. The lathe's basis is the machine body made of MINERALIT® polymer concrete. The working spindle is mounted on the front of the machine bod y on a compound slide, which completes movements in the X- and Z-axes. The turret is located below the working spindle and can hold up to twelve turning or driven tools. In addition, the VL 2 cnc turning machine can be equipped with a Y-axis in the turret.

The lathes are also ideally designed for use in assembly line production, as the VL 2 turning machines can be linked with simple automation components, such as conveyors , flip-over units, and changers.

Workpieces that can be machined with the lathe include flanges and gears. Here, combining the vertical lathes with other modular machines offers an efficient way to implement an assembly line for gears, for example. The cnc turning performed by the VL 2 is complemented by a subsequent process on a VL 4 H for the tooth hobbing and the use of a VLC 100 C for chamfering.

Advantages

Simple automation concept = high availability

Integrated automation, automatic workpiece changing

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.