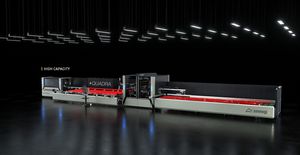

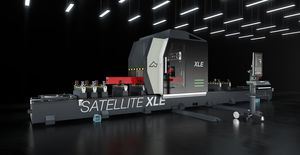

5-axis machining center SATELLITE X seriesverticalgantryfor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- gantry

- Machined material

- for aluminum, for steel, for PVC

- Applications

- cutting, drilling, heavy-duty

- Other characteristics

- milling, high-precision

- X travel

6,650 mm, 7,800 mm, 10,000 mm, 10,500 mm, 15,500 mm

(262 in, 307 in, 394 in, 413 in, 610 in)- Y travel

800 mm, 1,100 mm

(31 in, 43 in)- Z travel

525 mm, 655 mm

(21 in, 26 in)- Rotational speed

24,000 rpm

(150,796 rad.min-1)- Power

10 kW, 15 kW

(13.6 hp, 20.39 hp)

Description

5-axis CNC machining centre with moving gantry structure. Designed for milling, drilling, thread cutting and cutting on bars or workpieces of aluminium, PVC, light alloys in general and steel. The moving part of the machine consists of a gantry with precision rack and pinion drive. The high power (10 kW in S1) electrically-driven spindle with HSK-40E tool holder allows machining operations, including heavy-duty work, with optimum results in terms of speed and accuracy. A 9-place tool magazine is installed behind the moving gantry structure. The 300 mm blade is housed separately. The machine can be used in double mode so as to minimize machine downtime, as it is possible to change the workpiece (load/unload) in “concealed” time. It is also possible to load and consequently machine workpieces and to perform different operations differ between the two work areas. The gantry is provided with a guard which, besides protecting the operator, also reduces the noise impact on the environment.

The toolholder magazine specifically houses a 300 mm diameter disc blade holder cone, such a tool allows, with maximum speed, safety and precision, to perform compound cuts with respect to the A and B axes, as well as to perform straight cuts or end milling machining on the ends of the profile, in addition, trimming or cutting with respect to the X axis can be performed.

The machine can be optionally equipped with an electronic device that automatically corrects workpiece dimensional errors in length, width and height. In this way, the accuracy of the machine is not influenced by the differences between theoretic and actual workpiece dimensions during machining.

VIDEO

Catalogs

Related Searches

- CNC machining center

- Vertical CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Gantry CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- Horizontal CNC machining center

- Drilling CNC machining center

- Compact CNC machining center

- High-speed CNC machining center

- Heavy-duty CNC machining center

- Steel CNC machining center

- 32 outils CNC machining center

- Modular CNC machining center

- Copy router

- End milling machine

- Aluminum profile CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.