- Robotics - Automation - Industrial IT

- Industrial Software

- Control software

- ESPRIT by DP Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

Programming software SolidMill®CADCAD/CAMcontrol

Add to favorites

Compare this product

Characteristics

- Function

- programming, CAD, CAD/CAM, control, calculation

- Applications

- process, for CNC machines, 2-5 axis machining, for 2 to 5-axis laser cutting

- Type

- 3D, 2D

Description

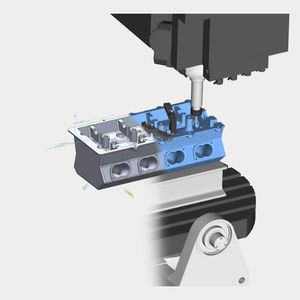

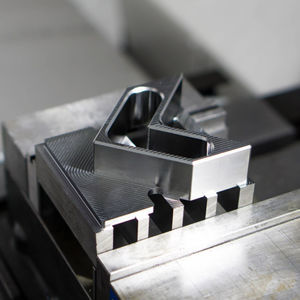

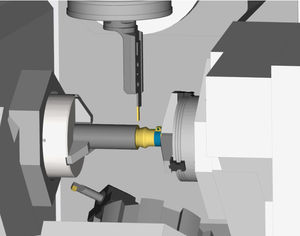

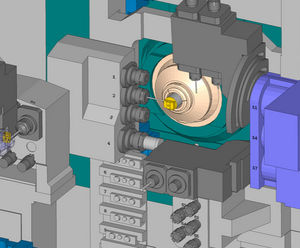

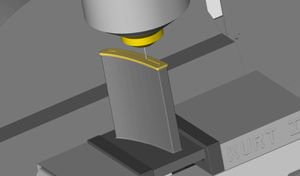

ESPRIT SolidMill® is a full-spectrum suite of milling cycles for facing, roughing, contouring and finishing, and hole making. With ESPRIT’s Modeless Programming™, these cycles are universally available on any class of CNC machine: vertical, horizontal, and gantry mills, millturn, and lathes — including Swiss-type. With SolidMill cycles, quickly generate efficient milling toolpaths while keeping extensive control over the movements of the cutting tool, supporting unique requirements of individual parts. Automatic calculation of the stock allows the system to generate efficient toolpaths while avoiding tool breakage and collisions. Machine-optimized G-code uses the advanced functions of the CNC, such as helical and polar interpolation, high-speed and high-precision options, and the machine’s built-in canned cycles.

In short, SolidMill:

Is a full-spectrum suite of milling cycles universally available for any class of CNC machine

Quickly generates toolpath with extensive control to support the unique requirements of each part

Produces edit-free, machine-optimized G-code

Model-Driven Machining

Starting from the CAD model, ESPRIT analyzes the part geometry to identify the machinable features. The machining cycles use the feature properties such as depth, draft, and hole style to minimize manual input, speeding the programming process and reducing the risk of error. Each feature is automatically associated with a workplane that drives a 4th or 5th axis to orient the workpiece. If the CAD model is updated, the associated toolpath is automatically updated to reflect the changes to the geometry.

Knowledge of the part is used to simplify programming

VIDEO

Catalogs

Related Searches

- Automation software solution

- Computer-aided design software

- Process software solution

- Control software solution

- 3D software solution

- Industrial software solution

- Simulation software

- Programming software

- Machine software

- EDM software

- 2D software

- Optimization software solution

- Planning software

- Calculation software

- High-performance software solution

- CAM software

- Inspection software

- CAD/CAM software

- Milling software

- Production software solution

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.