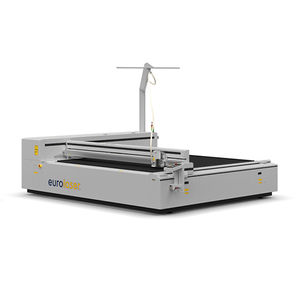

CO2 laser cutting machine XL-3200for plasticsfor acrylicsfor wood

Add to favorites

Compare this product

Characteristics

- Technology

- CO2 laser

- Material

- for plastics, for acrylics, for wood, for fabrics, for stone, for composite materials, for glass, for ceramics, for paper, for cardboard

- Product handled

- roller, panel, for foam panels, for packaging, die board, for flexible PU foam blocks, for identification nameplates, for carpets, adhesive tape, multi-ply fabric, single-ply fabric, strip fabric

- Control type

- CNC

- Associated function

- engraving, marking, contour, multi-function, milling, chamfering, labeling

- Applications

- for industrial applications, for the automotive industry, for aeronautical applications, for the electronics industry, for medical applications, for the toy industry, laboratory, for shipbuilding

- Workpiece loading

- with automated loading, automated loading/unloading

- Configuration

- large-format, gantry type, high-rail gantry type, flatbed, double table, multi-head, 3-axis

- Other characteristics

- CE, automatic, high-precision, high-speed, precision, high-performance, combined, with servo-motor, for mass production, multi-ply, metalloid, with inkjet printer, with optical registration, for ejection rubber production, robotic arm, modular, universal, for technical textiles, high-power, for large parts, with exchange table, with CCD camera, roller, programmable, ISO, robotic, for thin materials, small kerf, with automatic feeder, mechanical, electric, for plastic film, for heavy-duty applications

- X travel

2,270 mm

(89 in)- Y travel

3,200 mm

(126 in)- Maximum cutting height

Max.: 80 mm

(3.1 in)Min.: 58 mm

(2.3 in)- Cutting speed

Max.: 1.414 m/s

(4.639 ft/s)Min.: 0.001 m/s

(0.003 ft/s)- Laser power

Max.: 650 W

Min.: 60 W

Description

The laser machine, Laser Cutting Center XL-3200 evolution has a total processing dimension of 89.4" x 126" (2 270 x 3 200 mm) textiles with possible processing of 100" diameters from the roll. Smooth step-less cutting makes processing of extremely large formats achievable. Also, the versatile software package ensures no troubles in capture and transfer of data from other system providers. The automated transit unit option is of specific importance as it allows processing of numerous textile materials. The laser unit is based on a modular conception for exchange of important units.

For long-term value of your investment and low follow-up costs, The excellent grade sealed-off CO2 laser sources have no upkeep and the laser unit is integrated with a laser power range of 60 to 650 watts.

VIDEO

Catalogs

Product- and image brochure

33 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Eurolaser cutting machine

- Eurolaser CNC cutting machine

- Eurolaser laser cutting machine

- Eurolaser cutting machine for industrial applications

- Eurolaser automatic cutting machine

- Eurolaser high-precision cutting machine

- Eurolaser high-speed cutting machine

- Eurolaser plastic cutting machine

- Eurolaser precision cutting machine

- Eurolaser fabric cutting machine

- Eurolaser CE cutting machine

- Eurolaser high-performance cutting machine

- Eurolaser cutting machine for the automotive industry

- Eurolaser high-efficiency cutting machine

- Eurolaser engraving cutting machine

- Eurolaser bridge cutting machine

- Eurolaser CO2 laser cutting machine

- Eurolaser wood cutting machine

- Eurolaser cutting machine with automated loading

- Eurolaser stone cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.