- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Spray nozzle

- Guangzhou Cleaning Spray Equipment

- Products

- Catalogs

- News & Trends

- Exhibitions

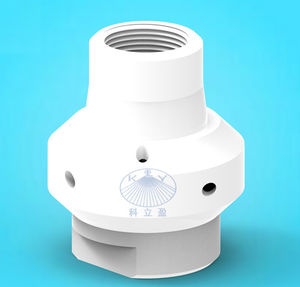

Cleaning nozzle SG sprayfor liquidsstainless steel

Add to favorites

Compare this product

Characteristics

- Function

- cleaning, spray

- Fluid

- for liquids

- Material

- stainless steel

- Applications

- for the food industry, for pharmaceutical applications, for tanks, chemical

- Other characteristics

- rotary, high-impact

Description

ModelSG4 tank cleaning nozzle

Material316L ss

BearingSlide bearing

Operating pressure3-7 bar

Max. pressure20 bar

Max. tank diameter4m

Diameter59mm

Filtrationline strainer with a mesh size of 80 or 100 mesh

Applicationhign efficient cleaning of tanks, equipment, etc

InstallationOperation in every direction is possible

Advantages

Controlled rotation

Pressure range up to 20 bar

Driven and lubricated by the cleaning fluid

Reliable slide bearing

Low-wear design

All materials are FDA-conform

The liquid flow powers the head by an internal turbine. Either a gear reduction or a hydraulic brake is used to control

the rotation. Hence the produced droplets are bigger and hit the tank wall with higher velocity. This rotary spray head keeps the speed of the head within its optimal range across a wider span of pressures, and the nozzles develops more powerful spray.

Design feature:

Driven by cleaning fluid, where the ball of the unit rotates at a slow speed, ensuring effective impingement of the cleaning solution on

the interior walls. SG tank cleaning nozzle offer improved cleaning over traditional static spray balls.

Precision Layout of hole ensure thoroughly cleaning.

Reliable slide bearing, low wear design

Application:

KLY rotary tank cleaning nozzles are well suited for small to medium sized tanks, such as dairy , food, pharmaceutical, beer, chemical,

industrial fermentation industry and the need for high impact cleaning occasions.

VIDEO

Other Guangzhou Cleaning Spray Equipment products

Tank cleaning nozzle

Related Searches

- Fitting

- Hydraulic fitting

- Screw-in fitting

- Pneumatic fitting

- Stainless fitting

- Spray atomizing nozzle

- Liquid atomizing nozzle

- Stainless steel atomizing nozzle

- Male fitting

- Cleaning atomizing nozzle

- Multi-jet atomizing nozzle

- Threaded nozzle

- Flat spray atomizing nozzle

- Air atomizing nozzle

- Brass atomizing nozzle

- Cooling atomizing nozzle

- Plastic nozzle

- Full-cone atomizing nozzle

- Compact fitting

- Atomizing nozzle for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.