- Machine-tools

- Cutting Tool

- Corner radius milling cutter

- MOLDINO Tool Engineering Europe GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

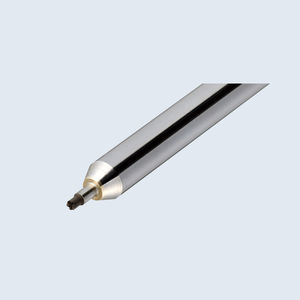

Corner radius milling cutter SCE-R end millsolidceramic

Add to favorites

Compare this product

Characteristics

- Geometry

- corner radius, end mill

- Construction

- solid

- Material

- ceramic

- Treated material

- for aluminum alloys, for titanium alloys

- Other characteristics

- high-efficiency, for high-speed cutting, with cylindrical shank, 6-flute

- Diameter

6 mm, 8 mm, 10 mm, 12 mm

(0.24 in, 0.31 in, 0.39 in, 0.47 in)- Length

60 mm, 70 mm, 80 mm

(2.36 in, 2.76 in, 3.15 in)

Description

Achieves high-efficiency machining for superalloy!

Achieves cutting speed of vc=800m/min.!

01 Achieves ultra-high-efficiency machining for superalloy.

02 The tools employ a special silicon nitride ceramics with excellent heat resistance that can withstand flute tip temperatures of more than 1000°C.

03 Cutting can be performed at much higher speeds than are normally used. By achieving cutting in the softening temperature region of the work material, tool life is greatly improved.

Features

Superalloy known as a difficult-to-cut material is a material that shows high strength even up to high temperatures, but when it reaches 1000 ° C or more, the material softens.

High speed cutting increases the cutting heat, and the cutting force of superalloy becomes almost the same as that of stainless steel.

In other words, the ceramic end mill that enables cutting in this temperature range realizes ultra-high-efficiency machining, greatly improving tool life.

Cautions on use

・Dry (air blow) cutting is recommended.

・Use of hydro chucks (hydraulic holders) or shrink-fit holders is recommended.

・Down cutting is recommended.

・Continuous cutting is recommended and interrupted cutting should be avoided as much as possible.

・When tool goes into the work material, a machining method that will gradually reach the set cutting depth is recommended.

・After cutting, the tool and tool holder will be at high temperatures. Pay sufficient attention when handling.

・Since heat-affected layers may be produced in the work material, a finishing allowance of at least 0.2 mm should be set.

VIDEO

Catalogs

SCE-R

6 Pages

Other MOLDINO Tool Engineering Europe GmbH products

Endmills

Related Searches

- Moldino milling cutter

- Moldino solid milling cutter

- Moldino steel milling cutter

- Drilling tool

- Moldino clamping milling cutter

- Solid drilling tool

- Moldino milling cutter with cylindrical shank

- Moldino metal milling cutter

- Moldino insert milling cutter

- Moldino end mill

- Moldino coated milling cutter

- Moldino cast iron milling cutter

- Moldino cutting milling cutter

- Moldino ball nose milling cutter

- Shell-end milling tool

- Moldino roughing milling cutter

- Face milling tool

- Moldino corner radius milling cutter

- Carbide drilling tool

- Moldino indexable insert milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.