- Industrial machines and equipment

- Mixing and Dosing

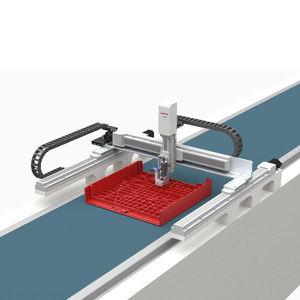

- Cartesian robot

- Janome Industrial Equipment

Cartesian robot JR3000 4-axis3-axisfor assembly

Add to favorites

Compare this product

Characteristics

- Type

- Cartesian

- Number of axes

- 4-axis, 3-axis

- Function

- for assembly, pick-and-place, dispensing, cutting, test, for production, screw tightening, surface treatment, for non-destructive testing

- Mounting

- benchtop

- Application domain

- for the food industry, for the automotive industry, for the pharmaceutical industry, for the electronics industry, for medical applications, laboratory, for small parts

- Other characteristics

- high-speed, compact, vision system, low-noise, high-precision

- Payload

Max.: 15 kg

(33.069 lb)Min.: 3.5 kg

(7.716 lb)- Reach

Max.: 620 mm

(24.41 in)Min.: 200 mm

(7.87 in)- Repeatability

Max.: 0.01 mm

(0.0004 in)Min.: 0.006 mm

(0.0002 in)

Description

Broaden your manufacturing potential with our flagship model desktop robot.

Increased Structural Rigidity

Faster, more precise, with greater structural rigidity for long-term, dependable use; high speed tracking function for increased stability.

We greatly shortened the after stop oscillation time for robots with a camera attached to the Z mechanism, cutting the waiting time between runs almost in half (compared with previous models).

Maximum speed 900mm/sec for model JR3300 and up; workpiece mass up to 15kg, tool mass up to 7kg.

Built-in robot cable; a first for our desktop robots.

Highly effective for manufacturing facilities with height restrictions. Z-axis cable is integrated into the Y-axes housing for a more streamlined design.

Field Network Compatibility

We've made the JR3000 Series Field network compatible for easy inclusion in automated assembly lines and automated work stations. Set program numbers, start/stop operations, acquire position data and overwrite programs, all through the Field network interface.

Multiple module types: choose among DeviceNet, Profibus, CC-Link, EtherNet/IP, PROFINET and CANopen.

LAN (Ethernet) port included as standard equipment

By connecting to your PC you can send and receive teaching data as well as monitor the operations of multiple robots.

Highly compatible for monitoring camera system installation

Enhanced camera functions to match the needs of assembly facilities aiming for finer precision.

In addition to our helpful position correction function, we've added functions such as an automatic calibration function and a CCD camera adjustment function.

Control up to 4 axes and 2 external motors with the Auxiliary

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Other Janome Industrial Equipment products

Desktop Robots

Related Searches

- Janome industrial robot

- Handling robot

- Floor-mounted robot

- Compact robot

- Janome high-speed robot

- 4-axis robot

- Janome assembly robot

- Janome applications robot

- Janome Cartesian robot

- Welding robot

- Robot for the food industry

- Janome 3-axis robot

- Palletizing robot

- Janome high-precision robot

- Janome robot for the electronics industry

- SCARA robot

- Janome robot for the pharmaceutical industry

- Janome robot for the automotive industry

- Janome dispensing robot

- Cutting robot

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.