- Machine-tools

- Cutting Tool

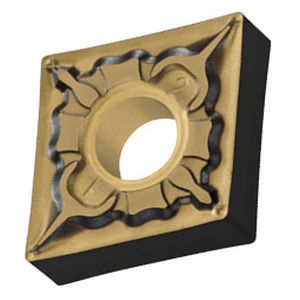

- Turning cutting insert

- MITSUBISHI MATERIALS

Turning cutting insert NX3035cermet

Add to favorites

Compare this product

Characteristics

- Function

- turning

- Material

- cermet

Description

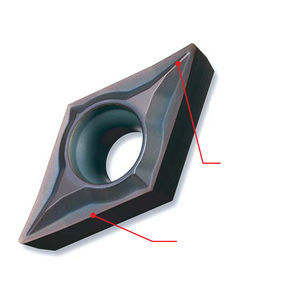

New Cermet Grade for Turning

Tough cermet grade for excellent component surface finishes

High resistance to fracture, thermal shock and wear

Special alloy substrate binder allows a secure wet cutting performance

The latest generation of cermet inserts for steel turning now provides cutting edge stability even when using coolant, an area where the use of conventional cermet grades resulted in unpredictable tool life.

A large range of over 300 inserts, with negative and positive geometries are available and the series also includes a varied range of chip breakers to suit all applications.

NX3035 uses a special alloy binder that offers even higher thermal conductivity and bonding strength, and as a result it delivers much improved thermal shock resistance. This reduces thermal cracking and enables NX3035 to exhibit a high degree of tool life stability even during wet machining, an area where conventional cermet lacks performance. Tests have shown that thermal shock resistance was doubled compared to other cermet grades.

The use of coolant during high speed finishing helps to maintain excellent surface finishes and additionally, dimensional accuracy of components can be maintained for longer due to the stability of the cutting edge.

Catalogs

NX3035 - Tough new cermet grade

20 Pages

C005E

1231 Pages

Related Searches

- Milling tool

- Solid milling tool

- Steel milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Milling tool with cylindrical shank

- Metal milling tool

- Insert milling tool

- End mill milling tool

- Indexable cutting insert

- Coated milling cutter

- Cast iron milling tool

- Hemispherical milling cutter

- General purpose drill bit

- Shell-end milling tool

- Roughing milling tool

- Face milling tool

- Carbide drilling tool

- Aluminum milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.