- Products

- Catalogs

- News & Trends

- Exhibitions

Multi-tube heat exchanger Kenics™liquid/liquidgas/liquidfor the food industry

Add to favorites

Compare this product

Characteristics

- Type

- multi-tube

- Fluid

- liquid/liquid, gas/liquid

- Applications

- for the food industry, for the plastics industry

- Operating pressure

Max.: 5,000 psi

Min.: 0 psi

Description

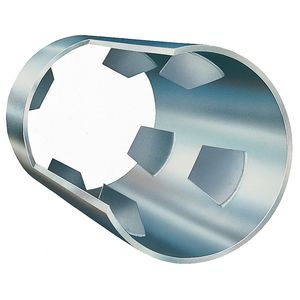

Kenics® Static Mixer technology, available exclusively in Kenics® Heat Exchangers, offers the highest available coefficients for fast, uniform heat transfer. Capable of reliable operation in a wide range of process applications, including those in the polymer, plastic, and food and beverage industries, Kenics Heat Exchangers require less space, less energy and less residence time than standard designs.

STATIC MIXING TECHNOLOGY

The Kenics Heat Exchanger consists of a continuous string of static mixer elements within each heat exchanger tube. Fluid flow is directed radially toward the pipe walls and back to the element, regardless of velocity. Additionally, momentum reversal and flow division also contributes to the mixing efficiency. All processed material is continuously and completely intermixed to eliminate radial gradients in temperature, velocity and material composition. As a result, Kenics Heat Exchangers provide predictable, controlled mixing, and the most efficient form of thermal transfer available today.

EFFICIENT HEAT EXCHANGER DESIGN

By using Kenics Static Mixer elements in each heat exchanger tube, the film build-up commonly associated with laminar flow empty tubes is significantly reduced. Process fluid is continuously pushed from the center of each tube, to the wall and back to the center, eliminating thermal gradients and boosting the inside film coefficient.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.