- Production Machines

- Other Manufacturing Equipment

- Rotor mill

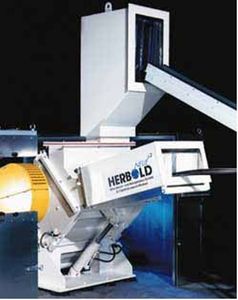

- NEUE HERBOLD Maschinen-u. Anlagenbau GmbH

Rotor mill SM Seriesfor PET bottleswaste

Add to favorites

Compare this product

Characteristics

- Technology

- rotor

- Product applications

- waste, for PET bottles

- Output

Max.: 5,000 kg/h

(11,023 lb/h)Min.: 1,000 kg/h

(2,205 lb/h)- Motor power

Max.: 250,000 W

(339.91 hp)Min.: 110 W

(0.15 hp)

Description

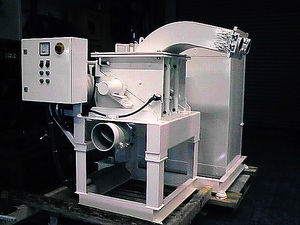

To increase the through-put rate of a granulator used for size reduction of loose, unpressed plastics a force feeding technique was developed.

Via conveyor the material is fed in the feed hopper. The transport to the grinding chamber is now no longer only based on the principle of gravitation - in fact the material is now fed to the grinding chamber by one / or more vertically assembled screws. Depending on the required granulator size the number of screws, the rotation speed as well as the drive capacity can vary. A transport screw equiped with a load-dependent control as well as a frequency converter prevents a rotor blockage caused by material accumulation. This results in a throughput rate which is ideal for the processed material. The wear protected design of the transport screw guarantees a long lasting operation time of the machine.

The features of this feeding method offer customers a number of advantages:

Especially suitable for size-reduction of plasticbottles, furthermore are canisters, packing materials from food production, as well as all thin walled hollow containers suitable materials for this feeding method.

Increased throughput rate.

The feed hopper is equiped with a worm gear shaft which enables a continuous material feed and prevents material swerve at the same time, which results in throughput increase of up to 30%.

Decreased sound- and power peaks.

The controlled material feed guarantees a constant, smooth rotor operation and therefore reduces sound peaks, which could occure by overfeeding. This constant material feed also prevents power peaks during the operation of the machine.

Exhibitions

Meet this supplier at the following exhibition(s):

Other NEUE HERBOLD Maschinen-u. Anlagenbau GmbH products

Granulators

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.