- Metrology - Laboratory

- Inspection and Monitoring

- Condition monitoring system

- New Infrared Technologies, S.L.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

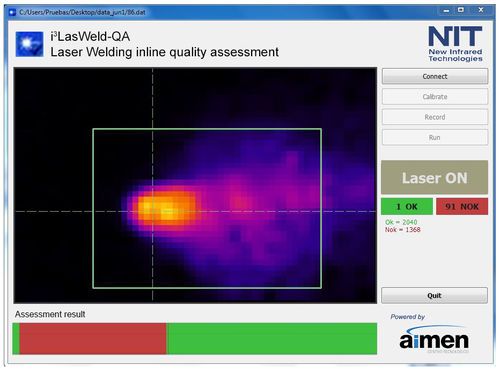

Condition monitoring system i3LasWeld alignmentlaser weldingfor the automotive industry

Add to favorites

Compare this product

Characteristics

- Type

- condition, alignment

- Applications

- laser welding

- Domain

- for the automotive industry, for the metallurgical industry

- Technology

- infrared

- Interface

- PoE

- Other characteristics

- real-time, remote, online, with integrated camera

Description

In line Infrared Imaging system for assessing in real time the quality of laser welding processes.

- The I3LASWELD system for the inline quality control of laser welding processes, capable of detecting defects in weld seams in real time and identifying defective parts.

- I3LASWELD provides high defects detection rates above 97%.

Defects:

- False friends

- Lack of penetration / lack of fusion

- Cracks, pores

- Underfilling

Main characteristics:

- Easy adapt to standard laser welding heads using C-mount optical interface

- The clasifier needs initial training

- Real-time defect detection during the welding process

- On-axis process observation using high-speed infrared imaging sensor (1 kHz)

VIDEO

Catalogs

Related Searches

- Digital camera system

- Infrared imager

- Industrial camera system

- Surveillance camera

- Vision processing camera

- USB camera module

- Waterproof camera system

- Compact camera module

- Detection imager

- Thermal camera

- GigE Vision camera

- Robust camera

- Temperature-controlled camera

- High-speed camera module

- Inspection camera system

- Power-over-Ethernet camera

- Machine vision camera module

- Laboratory camera module

- Measurement monitoring device

- Portable camera

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.