- Products

- Catalogs

- News & Trends

- Exhibitions

X-ray inspection machine XT H 450computed tomographyfor large partsindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- X-ray, computed tomography

- Applications

- for large parts

- Sector

- industrial

- Other characteristics

- high-resolution

- Output power

450 W

(1 hp)- Convey weight capacity

100 kg

(220 lb)

Description

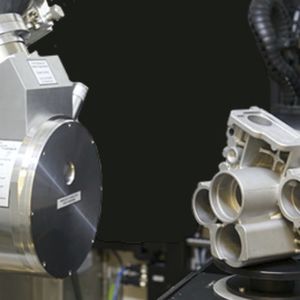

Unique 450kV microfocus X-ray and CT solution for high-resolution, non-destructive inspection of large and dense components like metal additive manufactured parts, metal alloy turbine blades and large castings.

Pushing the Boundaries of High-Voltage CT Inspection

Nikon’s unique 450kV microfocus source offers the necessary power to penetrate high-density parts, while achieving micron-accuracy with a spot size many times smaller than minifocus sources. Combined with the unique CLDA linear detector, sharp and scatter-free images are produced, while high-sensitivity flat panel detectors reduce scan times.

Unique 450kV Microfocus Source

Nikon’s 450kV/450W microfocus X-ray source is the only one in the world to offer high-energy combined with a high-resolution focal spot size of 80μm to allow inspection of dense components.

Rotating Target for Ultimate Resolution

Nikon’s 450kV microfocus source utilises unique Rotating Target 2.0 technology to achieve ultimate resolution or cut scan times with only 120μm spot size at 450W.

Scatter-Free CT

Nikon’s in-house CLDA (Curved Linear Detector Array) is a high-sensitivity linear detector specifically designed for Nikon’s 450kV microfocus source that doesn’t capture the undesired scattered X-rays resulting in stunning, scatter-free images.

VIDEO

Catalogs

Related Searches

- Nikon Metrology measuring system

- 3D scanning system

- Inspection machine

- Optical measuring machine

- Laser scanning system

- Measurement scanning system

- Automatic measuring machine

- High-precision measuring machine

- Measuring system for industrial applications

- Nikon Metrology parts measuring system

- Distance measuring machine

- Inspection scanning system

- Control measuring machine

- Nikon Metrology laser measuring system

- High-resolution scanning system

- Non-contact measuring machine

- High-speed scanning system

- Diameter measuring machine

- Automatic inspection machine

- Nikon Metrology video measuring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.