Doppler ultrasonic flow meter OCM Ffor liquidsclamp-onwall-mounted

Add to favorites

Compare this product

Characteristics

- Technology

- Doppler ultrasonic

- Fluid

- for liquids

- Installation

- clamp-on, wall-mounted

- Material

- plastic

- Communication

- 4-20 mA, digital output

- Supply voltage

- 24 Vdc, 110VAC, 240 VAC

- Protection level

- IP65

- Applications

- industrial, for wastewater treatment

- Other characteristics

- with display, open-channel

- Process temperature

Max.: 70 °C

(158 °F)Min.: -30 °C

(-22 °F)

Description

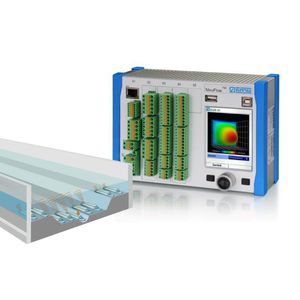

For ultrasonic flow measurement of slight to heavily polluted media in part filled an full pipes and channels. Complete measurement system in connection with KDA sensors

-Reasonable purchase costs

-Reliable, with more than 30 years of product experience

-Easy mounting without additional constructions

-Integrated 3-step controller

-Measurement in heavily polluted and abrasive media

General Description

The OCM F flow metering system utilises a fully bidirectional ultrasonic velocity sensor.

The intelligent Doppler sensor detects and directly evaluates the flow velocity. Other than with mag meters, this method has an absolutely stable zero point. Moreover, the dynamic measurement range for minimum level and flow is very high. Level measurement can be carried out either by a sensor-integrated pressure cell or by using an external sensor.

Operation / Programming

Thanks to the intuitive user interface it is very easy to set up the OCM F for the requirements of various applications. Additional input devices like Computers etc. are not needed. Programmed settings are indicated clearly.

Measurement principle

The measurement principle is based on the classic Doppler method where an ultrasonic signal with a defined frequency is transmitted into a liquid at a known angle. A portion of the ultrasound energy is reflected by the solid particles or gas bubbles carried with the liquid. Due to the movement of the particles a frequency distortion occurs which is direct proportional to the particle velocity. The flow velocity can be determined from this frequency shift subsequently.

Catalogs

OCM F

4 Pages

Nivus OCM F

4 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- NIVUS flow meter

- NIVUS liquid flow meter

- Level limit switch

- NIVUS level sensor

- Liquid level limit switch

- NIVUS liquid level sensor

- Stainless steel flowmeter

- NIVUS waterproof flow meter

- Industrial flowmeter

- Float level switch

- NIVUS analog level sensor

- In-line flowmeter

- NIVUS precision flow meter

- NIVUS compact flow meter

- Water flowmeter

- Level transmitter

- Digital output level sensor

- Stainless steel level limit switch

- Liquid level transmitter

- DC flowmeter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.