- Robotics - Automation - Industrial IT

- Industrial Software

- Quality control software

- OTC DAIHEN EUROPE GmbH

Monitoring software FD-AMfor quality controlfor welding applications

Add to favorites

Compare this product

Characteristics

- Function

- monitoring, for quality control

- Applications

- for welding applications

Description

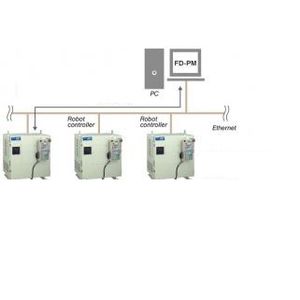

PC arc monitor FD-AM

Welding quality control by PC

VISUAL DISPLAY OF WELDING CONDITION

This monitor displays the welding current, welding voltage, and wire feeding load graphically. It can also display detailed start condition and state of robot controller

WELDING CONDITIONS CAN BE SAVED!

The number of times of welding, number of occurrence of failures, task program number, welding time, and average current can be saved.

* The storable capacity depends on the capacity of hard disk of your PC.

Quality control for every workpiece

An alarm output or abnormal threshold can be identified for each workpiece by inputting the workpiece number in the robot controller. This monitor supports detection of failure of workpieces.

QUALITY CONTROL FOR EVERY WORKPIECE

An alarm output or abnormal threshold can be identified for each workpiece by inputting the workpiece number in the robot controller. This monitor supports detection of failure of workpieces.

MONITORING ACCURACY IMPROVED

The sampling frequency is increased 10 times compared to the conventional method, allowing detection of instantaneous arc outage or outage in short tack welding.

Catalogs

No catalogs are available for this product.

See all of OTC DAIHEN EUROPE GmbH‘s catalogsRelated Searches

- Automation software solution

- Process software solution

- Control software solution

- Monitoring software solution

- Simulation software

- Programming software

- PLC software

- Editing software

- Storage software

- Quality control software solution

- Off-line software

- Robot software

- Software for welding applications

- Welding robot software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.