- Metrology - Laboratory

- Laboratory Equipment

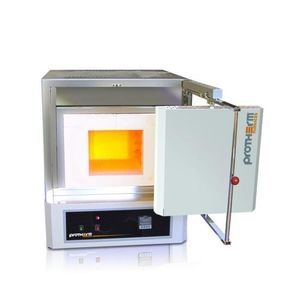

- Sintering oven

- Protherm Furnaces

Sintering furnace MOS serieschamberelectric resistancehigh-temperature

Add to favorites

Compare this product

Characteristics

- Function

- sintering

- Configuration

- chamber

- Heat source

- electric resistance

- Other characteristics

- high-temperature, programmable, compact, vertical, large-size, benchtop, laboratory, for metallurgy

- Maximum temperature

1,550 °C, 1,600 °C, 1,700 °C, 1,800 °C

(2,822 °F, 2,912 °F, 3,092 °F, 3,272 °F)- Capacity

Max.: 15.8 l

(4.17 gal)Min.: 1.3 l

(0.34 gal)- Width

51 cm, 58 cm, 62 cm, 82 cm, 92 cm

(20.08 in, 22.83 in, 24.41 in, 32.28 in, 36.22 in)- Height

66 cm, 70 cm, 71 cm, 77 cm, 145 cm

(25.98 in, 27.56 in, 27.95 in, 30.31 in, 57.09 in)- Depth

47 cm, 51 cm, 52 cm, 61 cm

(18.5 in, 20.08 in, 20.47 in, 24.02 in)

Description

MoS series have been used as trusted professional chamber furnaces for many years in laboratories. Available with brick and fiber insulation elements, with a wide variety of options, these models can be optimally used for high temperature procedures.

Standard MoS series furnaces cover a range from 1600°C to 1800°C, all of which have front loading for easy operation and double skin construction to maintain a cooler outer case.

Important advantage of the model is that element change is very easy and economic. Furnaces starting from 1800°C use high quality Molybdenum Disilicide heating elements, providing a very long service life.

Galvanized coating covered epoxy painted structure, providing longer life time and aesthetics.

Typical applications for the product is almost all high temperature applications where high level of precision is required; high temperature sintering processes such as Ceramic, Dental and Material Research.

System Features

Vertical counter balanced door

Standard door safety switch

Customized controller option

High-quality fiber material

High level temperature uniformity

Bottom protection, alumina plates on the floor

Standard brick design on the outer skirts of the door and the furnace opening providing protection from possible unwanted damages during loading and unloading.

Table top and Self-Standing design

High quality heating elements ensuring a long service life

System operation with solid-state-relays

Short heating times

Electrical protection

Dual skin housing for low external temperatures and high inner temperature stability

Easy replacement of heating elements

Intuitive controller user interface

Catalogs

High Temperature MoS Series

2 Pages

Furnaces & Ovens 2018

56 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Tunnel furnace

- Controlled atmosphere furnace

- High-temperature furnace

- Vacuum furnace

- Continuous furnace

- Melting furnace

- Thermal furnace

- Programmable furnace

- Horizontal furnace

- Sintering furnace

- Vertical furnace

- Compact furnace

- Custom furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.