- Production Machines

- Forming Machine

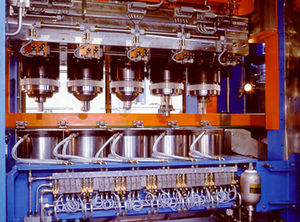

- Hydraulic press

- SCHULER - MÜLLER WEINGARTEN

Hydraulic press MH drawingforgingironing

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- drawing, forging, ironing

- Control

- fully-automatic

- Applications

- for production

- Force

8,000 kN, 12,000 kN, 19,000 kN

Description

As a rule, one ironing operation is sufficient for calibrating precise parts. Long, thin walled parts are generated in one stroke by relatively large reductions in the wall thickness on presses with long stroke length and several ironing rings arranged consecutively. The blanks are pulled through the die with the punch. In one cycle, the wall thickness is reduced precisely to the required dimension, the ultimaManufacturing CNG gas cylinder tanks from blanks offers many advantages. Blanks are easier and less expensive to manufacture than seamless precision tubes. In addition, they have thinner bottoms compared to containers forged from a solid block. High surface quality is guaranteed by the integrated ironing process. Fully automated production processes and fast changeovers maximize productivity for the system.

te shape is created and the surface is smoothed.

Your advantages

lower material cost of blanks as compared to precision tubes

lower weight than traditionally forged containers

larger container diameters are possible compared to traditional forging

high surface quality

Catalogs

The entire world of forging

84 Pages

Other SCHULER - MÜLLER WEINGARTEN products

Forging Technology

Related Searches

- Schuler industrial press

- Schuler hydraulic press

- Schuler forming press

- Schuler automatic press

- Pneumatic press

- Electric press

- Schuler cutting press

- Schuler stamping press

- Ram press

- Schuler mechanical press

- PLC-controlled press

- Schuler production press

- Bending press

- C-frame press

- Schuler press for the automotive industry

- Cambering press

- Process press

- Press for industrial applications

- NC press

- Compact press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.