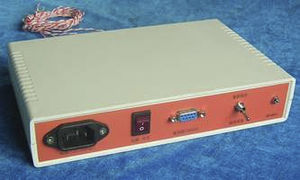

Reflow soldering oven AE-8800 semi-automaticfor PCB

Add to favorites

Compare this product

Characteristics

- Technique

- reflow

- Operating mode

- semi-automatic

- Applications

- for PCB

Description

Reflow principles:

The Reflow oven contains multiple zones, which can be individually

controlled for temperature. Generally there are several heating zones followed

by one cooling zone. The PCB moves through the oven on a conveyor belt, and is

therefore subjected to a controlled time-temperature profile. The speed of the

conveyor can also be controlled.

Heating Element:

The heat source is from ceramic heaters, which transfers the heat to the assemblies by

means of convection, the oven will have fans to force heated air towards the PCB.

Conveyor:

The PCB will travel into the heating zones by means of mesh conveyor or chain driven

conveyor (depending on your model) The conveyor can be program to move from

left to right or right to left. The speeds are adjustable by software.

Profiler:

The reflow oven will come with a build-in three point profiler. Thermal profiling is the

process of plotting temperature vs. time of the PCB as it travels through the oven.

The PCB thermal profile is determined by temperature, time, and heat transfer

rate.

Catalogs

No catalogs are available for this product.

See all of SMT MAX‘s catalogsRelated Searches

- Automatic crimp applicator

- Industrial fume extractor

- Mobile fume extractor

- Mounting machine

- Soldering machine

- Automatic mounting machine

- Reflow soldering machine

- Compact crimping machine

- Automated soldering machine

- Printed circuit soldering machine

- Wire crimp applicator

- Soldering station

- Connector crimping machine

- Wave soldering machine

- Semi-automatic soldering machine

- Fully-automatic crimping machine

- Tape feeder

- Micro-welder

- Electronic components assembly machine

- ESD soldering station

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.