- Products

- Catalogs

- News & Trends

- Exhibitions

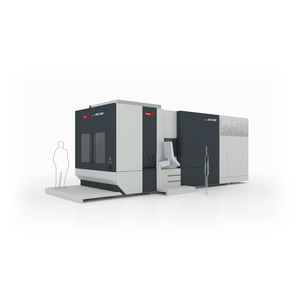

5-axis CNC machining center Heckert X series horizontalHSK A-63HSK-A 100

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Spindle mount

- HSK A-63, HSK-A 100

- Applications

- for large workpieces

- Other characteristics

- high-productivity, high-precision, high-rigidity, modular

- X travel

700 mm, 850 mm

(28 in, 33 in)- Y travel

750 mm, 1,020 mm

(30 in, 40 in)- Z travel

750 mm, 1,000 mm

(30 in, 39 in)- Work feed X-axis

80,000 mm/min

(52 in/s)- Work feed Y-axis

80,000 mm/min

(52 in/s)- Work feed Z-axis

80,000 mm/min

(52 in/s)- Table load capacity

400 kg, 700 kg

(882 lb, 1,543 lb)- Overall length

6,750 mm, 7,630 mm

(265.7 in, 300.4 in)- Overall width

2,840 mm, 2,960 mm, 3,980 mm

(111.8 in, 116.5 in, 156.7 in)

Description

These five-axis horizontal machining centres are space-saving miracles, but they remain true to our stringent quality standards in every respect. They guarantee maximum precision for your work processes thanks to our guiding values of accuracy and rigidity. These are values embodied by Heckert machining centres throughout their decades-long history on the market.

Designed to your benefit

The basic modular concept of the new Heckert machining centres offers maximum efficiency even with a standard configuration. And that's no coincidence, since a consistent increase in added value for the customer was essential for the development of each individual assembly.

Basic machine – Increased process reliability

Maintenance-free cover concept with fixed sheet steel panels

High level of rigidity and damping

Direct chip disposal, even for dry machining

Footprint – Reduced investment costs

Footprint reduced by 38%

Periferical units are fully integrated

Fifth axis – Reliability in the manufacturing process

Unique level of stability thanks to bearings on both sides

Maximum accuracy thanks to thermal-symmetric design

Maximum dynamics in positioning mode and simultanious operation

Excellent chip disposal

Column – Maximum productivity

Thermo-symmetrical design

High level of rigidity

Direct chip disposal, even for dry machining

Optimised for dynamic machining

VIDEO

Catalogs

No catalogs are available for this product.

See all of Starrag‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- Precision CNC machining center

- 2-axis turning center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- 3-axis turning center

- Drilling CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.