- Products

- Catalogs

- News & Trends

- Exhibitions

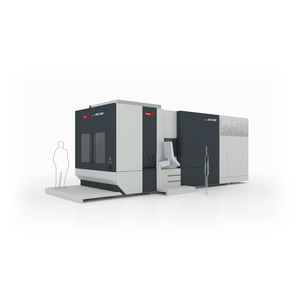

4-axis machining center Heckert H serieshorizontalHSK A-63cutting

Add to favorites

Compare this product

Characteristics

- Number of axes

- 4-axis

- Spindle orientation

- horizontal

- Spindle mount

- HSK A-63

- Applications

- cutting

- Other characteristics

- high-productivity, high-precision, high-rigidity, modular, automated loading/unloading

- X travel

700 mm

(28 in)- Y travel

750 mm

(30 in)- Z travel

780 mm

(31 in)- Work feed X-axis

65,000 mm/min, 80,000 mm/min

(43 in/s, 52 in/s)- Work feed Y-axis

65,000 mm/min, 80,000 mm/min

(43 in/s, 52 in/s)- Work feed Z-axis

80,000 mm/min

(52 in/s)- Table load capacity

600 kg, 800 kg, 1,000 kg, 1,500 kg

(1,323 lb, 1,764 lb, 2,205 lb, 3,307 lb)- Tool-changing time

9 s, 9.5 s

- Overall length

6,800 mm, 7,630 mm, 7,950 mm

(267.7 in, 300.4 in, 313 in)- Overall width

2,670 mm, 2,760 mm, 2,960 mm, 3,300 mm, 3,860 mm

(105.1 in, 108.7 in, 116.5 in, 129.9 in, 152 in)

Description

These four-axis horizontal machining centres are space-saving miracles, but they remain true to our stringent quality standards in every respect. They guarantee maximum precision for your work processes thanks to our guiding values of accuracy and rigidity. These are values embodied by Heckert machining centres throughout their decades-long history on the market.

Basic machine – Increased process reliability

Maintenance-free cover concept with fixed sheet steel panels

High level of rigidity and damping

Direct chip disposal, even for dry machining

Footprint – Reduced investment costs

Footprint reduced by 38%

Periferical units are fully integrated

Column – Maximum productivity

Thermo-symmetrical design

High level of rigidity

Direct chip disposal, even for dry machining

Optimised for dynamic machining

Work spindle – A clear competitive edge

Up to 350 Nm torque

Up to 20,000 rpm

Extremely short speed-up time with HSK-A63

Tool magazine – Less non-productive time

Up to 450 tools

Individually configurable

Ergonomic loading and unloading

Also with tool identification

Pallet changer – More flexibility

9-second pallet change time

Set-up during machining time

Automatic loading doors (option)

Workpiece carrier – Safe loading and unloading

13-channel hydraulic clamping unit

Maximum precision for machine pallets

Individually adaptable

VIDEO

Catalogs

No catalogs are available for this product.

See all of Starrag‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- 3-axis CNC machining center

- CNC turning center

- Precision CNC machining center

- 2-axis turning center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- 3-axis turning center

- Horizontal CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.