- Production Machines

- Cutting Machine

- Fiber laser cutting machine

- Suzhou Suntop Laser Technology CO.,LTD

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

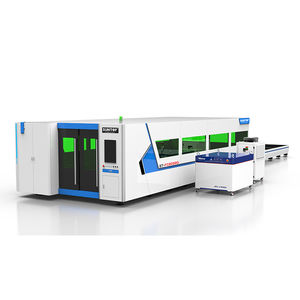

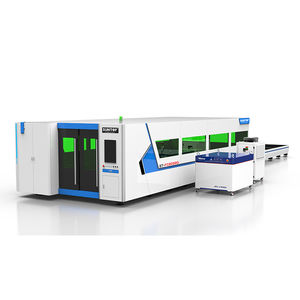

Fiber laser cutting machine ST-FC8025-3000Ffor metalfor carbon steelsheet metal

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal, for carbon steel

- Product handled

- sheet metal

- Control type

- CNC

- Configuration

- 3-axis

- Other characteristics

- automatic, high-precision, high-speed, precision, CE, high-performance

- X travel

2,550 mm

(100 in)- Y travel

8,100 mm

(319 in)- Cutting speed

Min.: 1,000 mm/min

(0.656 in/s)Max.: 35,000 mm/min

(22.966 in/s)- Laser power

1,000 W, 1,500 W, 2,000 W, 3,000 W, 6,000 W

Description

1.1. The cutting quality is good:

Cutting knife is narrow and parallel on both sides, also perpendicular to surface, dimensional accuracy of cutting pieces can be up to + / - 0.05 mm, the cutting surface is smooth and beautiful, the surface roughness is only a few dozen microns, laser cutting can be used as the final working procedure, parts can be even used directly without mechanical processing,heat affected zone is very small, material performance is hardly affected near the kerf width ,the workpiece deformation is small. Also, kerf geometry is good , slitting rectangular cross-section shapes appear to be regular.

1.2. Highly automation:

Adopts digital control, you only need to use CAD to draw the picture and import to specialized software, laser cutting machine can cut out the artifacts you need, moreover there is intelligent typesetting function, thus can save raw material costs to the greatest extent.

1.3. High cutting efficiency:

Due to the transmission properties of laser, laser cutting machine has equipped with many sets of CNC work bench to realize numerical control. You only need to change the CNC program to cut different shape, as well as for two-dimensional cutting, and three-dimensional cutting,there is no contact for work piece and laser head, so there is no tool wear. No need to change "tool" for different shapes parts processing, only need to change the output parameters. Laser, low noise, small vibration, and no pollution while cutting.

Catalogs

No catalogs are available for this product.

See all of Suzhou Suntop Laser Technology CO.,LTD‘s catalogsOther Suzhou Suntop Laser Technology CO.,LTD products

Fiber Laser Cutting Machine-Full Enclosed

Related Searches

- SUNTOP cutting machine

- SUNTOP metal cutting machine

- SUNTOP CNC cutting machine

- SUNTOP laser cutting machine

- SUNTOP cutting machine for industrial applications

- SUNTOP automatic cutting machine

- SUNTOP high-precision cutting machine

- SUNTOP sheet metal cutting machine

- SUNTOP high-speed cutting machine

- SUNTOP fiber laser cutting machine

- SUNTOP tube cutting machine

- SUNTOP plastic cutting machine

- SUNTOP precision cutting machine

- SUNTOP fabric cutting machine

- SUNTOP aluminum cutting machine

- SUNTOP stainless steel cutting machine

- Sheet cutting system

- SUNTOP CE cutting machine

- SUNTOP metal fabrication cutting machine

- SUNTOP high-performance cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.