Plastic screw TPX pan headFrearsonstainless steel

Add to favorites

Compare this product

Characteristics

- Applications

- for plastics

- Head

- pan head

- Drive type

- Frearson

- Materials

- stainless steel

- Other characteristics

- self-tapping

Description

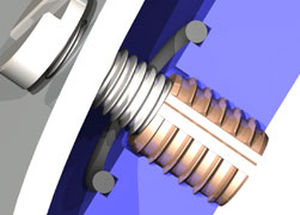

The Tappex TPX thread forming screws (not thread cutting) are designed to be used in most thermoplastic materials. These screws can be installed into drilled or moulded holes in a wide variety of applications. Tappex TPX screws are produced by cold forging, not machined from bar or wire and therefore have good inherent mechanical properties with minimum residual stress. Typically the workpiece material or substrate will relax as the screw rotates during installation and then shrink back, a little.

Thread Forming Screws® – Features

Range of diameters and thread lengths

Philips or Recessed Star Drive

Hardened steel with a zinc and clear passivate

Stainless steel 303 grade

30 degree thread flank angle offers the following benefits:

Reduced installation torque

Reduced potential for over tightening

Reduced stress induced in the plastic. (care should be taken with notch sensitive plastics)

With care the TPX screw can be re-installed multiple times

Thread Forming Screws® – Design Considerations

For successful installation and application a number of factors should be taken into consideration:

Hole size and design – recommended hole geometry available from Tappex (See ETP 45 downloadable from Tappex website)

Type and grade of Plastic

Boss wall thickness – to withstand installation forces and maximise performance

Installation depth

Required application and strip out performance

For advice, please contact our Applications Engineering Department with your specific requirements.

Related Searches

- Screw

- Threaded insert

- Metal insert

- Steel screw

- Round insert

- Cylindrical head screw

- Stainless steel screw

- Nickel-plated brass insert

- Stainless steel insert

- Plastic insert

- Steel insert

- Phillips screw

- Press-in insert

- Self-tapping insert

- Molded-in insert

- Flat insert

- Plastic insert

- Self-tapping screw

- Ultrasonic installation insert

- Plastic screw

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.