- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

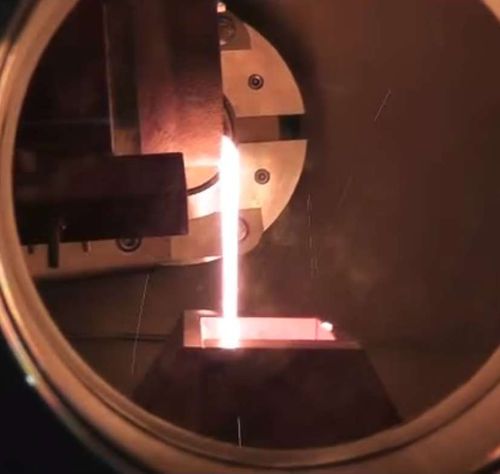

Melting furnace TVMbellinductionhigh-vacuum

Add to favorites

Compare this product

Characteristics

- Function

- melting

- Configuration

- bell

- Heat source

- induction

- Atmosphere

- high-vacuum

Description

TVM are furnaces designed for vacuum induction melting. They are applicable for melting under vacuum conditions of titanium, TiAl, stainless steel, nickel-based super alloys and other unconventional alloys.

TOPCAST has manufactured this class of furnaces according to different customized specifications of Ti crucible capacity, flask mould size and vacuum level.

The plant is structurally separated into 6 different sub-systems such as Vacuum Melting Chamber, Induction Generator, Tilting Coil and Crucible Assembly, Casting Mold, Vacuum Pump and Monitoring System.

Crucible can be prepared in different ceramic materials or in copper-sliced water cooled.

The crucibles for Ti can avoid alloy contamination and they can withstand the high thermal and chemical shocks due to Ti melting. The cold-crucible systems are also available for the larger power requirement.

In order to avoid alpha-case structure in the cast parts, TOPCAST has been designed an investment powder for Titanium casting.

The system also include monitoring System for process data collection, vacuum leakage detector and oxygen analyzer and RS232 and USB interfaces.

VIDEO

Catalogs

TOPCAST Product Catalogue

15 Pages

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Controlled atmosphere furnace

- Industrial furnace

- Vacuum furnace

- Melting furnace

- Electric resistance furnace

- Inert gas furnace

- Muffle furnace

- Rotary furnace

- Induction furnace

- Nitrogen furnace

- Bell furnace

- Car bottom kiln

- Steel furnace

- Pit furnace

- Casting furnace

- Precious metal furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.