- Production Machines

- Forming Machine

- Pipe-end forming machine

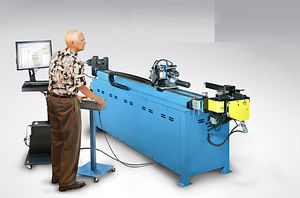

- Winton Machine Company

Pipe-end forming machine E50 metalhydraulic

Add to favorites

Compare this product

Characteristics

- Product handled

- pipe-end

- Treated material

- metal

- Other characteristics

- hydraulic

Description

Product Description

All tube end formers are designed and tested in house. We use standard purchased components to build every tube end forming machine. We at Winton are proud of the quality of every end former sold. Please, call us today and ask how the quality of the end forming machines we build will translate into quality end formed tubes on your shop floor.

The model E50 tube end former is a production machine used to expand the end of a tube. The end former uses 8 segmented fingers to minimize the tooling marks on the tube as the tube expands. No clamp die is used for this process. This means you can have a bent tube close to the end of the tube and still expand the tube. The user inserts the tube over the die fingers and then cycles the end former. Once the ram stroke is complete, the hydraulic control valve automatically returns the ram to its home position.

Model: E50 Tube End Former

Tube Capacity: 2" OD tubing

Repeatability: ± .002" on the diameter

Tooling style: quick change

Max. Pressure: 1500 psi

Expand time: 3 seconds

Expand time: 1 second, optional

Loader/unloader: optional

Drop-in tooling, quick change

Fine thread adjustment on expanded diameter

NEMA enclosure contains all 24V DC logic

Dual palm switches for safe operation (optional)

Catalogs

No catalogs are available for this product.

See all of Winton Machine Company‘s catalogsOther Winton Machine Company products

Tube Fabrication Machines

Related Searches

- Bender

- Tube bender

- Hydraulic bender

- Electric bender

- CNC bender

- Automatic bender

- Forming machine

- Manual bender

- Mandrel bender

- Metal forming machine

- Digitally-assisted bending machine

- Compact bender

- Handheld bender

- Hydraulic forming machine

- Pipe-end forming machine

- XYZ bending machine

- Servo-electric bending cell

- Forming bending machine

- Tube forming machine

- PLC-controlled forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.