- Products

- Catalogs

- News & Trends

- Exhibitions

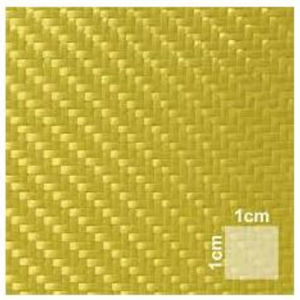

Rubber elastomer VICWA®

Add to favorites

Compare this product

Characteristics

- Material

- rubber

Description

VICWA rubber Engineered Elastomer is a kind of modified para-aramid chopped fiber which can be used as a compounding agent to improve the properties of vulcanized and peroxide-vulcanized rubber compounds. VICWA rubber Engineered Elastomer can improve toughness, tear resistance and fatigue resistance while reducing hysteresis, heat accumulation and friction.

VICWA rubber Engineered Elastomer can be used to reduce the hysteresis of carbon black compounds and compounds containing carbon black and silicon dioxide. When the Engineered Elastomer is mixed with the compound at high temperature, the resulting direct reaction product reacts with the carbon black particles, thereby reducing the interaction between the fillers (enhancing the Payne effect). The resulting compound has a lower frictional energy, which improves the hysteresis properties. The reaction takes place at 150~160°C using carbon black as catalyst. This type of reaction is suitable for compounds containing both natural rubber (NR) and synthetic rubber (SR).

Tyre made with VICWA rubber master particles are more durable and, due to less rolling resistance, can improve vehicle fuel efficiency without affecting performance, helping to improve the performance of truck/bus (T/B) tyre, engineering machinery tyre (OTB) and agricultural vehicle tyre. In addition, it is beneficial to other rubber products and composite material reinforcing agents and other related applications.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.