Quenching furnace Tcarbonitridingmuffleconveyor

Add to favorites

Compare this product

Characteristics

- Function

- quenching, carbonitriding

- Configuration

- muffle, conveyor

- Heat source

- electric

- Other characteristics

- continuous

Description

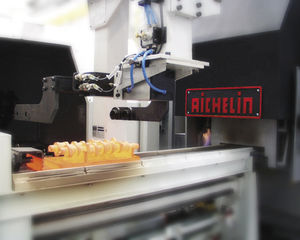

MESH BELT FURNACE T

The furnace type T is developed for continuous heat treatment of large and small series in continuous operation. It can be optimally integrated into the series production process. High precision and reproducibility of the results allow metallurgical and mechanical properties to be achieved for a wide range of parts.

The systems can be electrically or gas-heated. Type T furnaces are suitable for protective gas heat treatment of serial metal parts which are subject to high quality requirements.

The T series is available in three basic types:

T: Plant with muffle for better protective gas guiding

TC: Plant without muffle

TCR: Plant without muffle with roller-supported belt

PROCESSES

Hardening by oil, water and polymer quenching

Case-hardening

Carburizing

Carbonitriding

Bainite and martensite hardening by salt quenching

Nitrocarburizing using the Safed OXYCAD® process

COMPONENTS

Mass produced parts for the automotive industry

Screws and other fastening elements

Roller bearing parts

Fine-blanking and deep-drawing parts

Components for drive chains

Tools such as saw blades, drills or screwdrivers

Any kind of small parts

Catalogs

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Combustion furnace

- Gas furnace

- Tunnel furnace

- Industrial furnace

- Automatic furnace

- Continuous furnace

- Annealing furnace

- Quenching furnace

- Compact furnace

- Conveyor furnace

- Tempering furnace

- Aging furnace

- Muffle furnace

- Hardening furnace

- Rotary furnace

- Preheating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.