- Machine-tools

- Finishing Machine

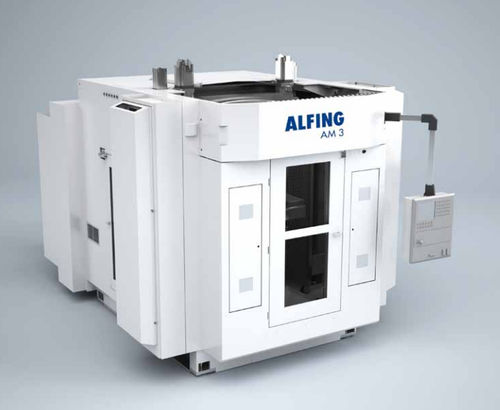

- CNC finishing machine

- Alfing Kessler Sondermaschinen GmbH

Machining finishing machine AM series CNCmulti-spindleCNC

Add to favorites

Compare this product

Characteristics

- Associated function

- machining

- Type

- CNC

- Other characteristics

- multi-spindle, CNC

Description

PERFECTION IN THE HIGH PERFORMANCE CONNECTING ROD MACHINING SEGMENT

THE PERFECT SOLUTION

With an impressive manufacturing capacity and flexibility, the AM offers the best results and conditions for the machining of connecting rods.

This is why the manufacturing module is an essential factor of success for a production segment from 500,000 to 1,300,000 connecting rods per year.

SUCCESS FACTORS OF THE AM

Maximum efficiency

Flexibility

Safe access and good overview

Reduction of footprint compared to competitors’ machines

Time-saving installation and relocating

Favorable thermal characteristic

Optimized chip disposal

Less energy consumption, less wear and tear

Machining with retracted Z-axis for highest precision

MAIN PRINCIPLE OF THE MACHINE

The main principle of the machine

A spindle row dedicated to each process step – this is the main principle of the AM. Tool change is not necessary, tool changing times do not apply. The advantages of this concept: high efficiency and low energy consumption.

Ideal process layout

With the individual process layout, Alfing’s longtime experience in machining connecting rods becomes apparent. That way the machine’s full potential comes into play.

All machining steps in one setup

With the AM, spindles can be arranged at both sides as well as on the top of the machining area. Therefore, pre-machining and bolt hole machining or entire finish machining can be done in only one setup. All that takes place in an optimized work envelope.

Chip-to-chip time less than one second

Compared to a machining center the AM does not require tool changing. Chip-to-chip time is less than one second between spindle rows, which are next to each other.

Catalogs

FIXTURE SPINDLE TECHNOLOGY

40 Pages

HANDHELD NUTRUNNER TECHNOLOGY

48 Pages

Other Alfing Kessler Sondermaschinen GmbH products

CON ROD MACHINING

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.