- Industrial machines and equipment

- Welding and Assembly

- Seam welding

- ANCOFERWALDRAM STEELPLATES B.V.

- Products

- Catalogs

- News & Trends

- Exhibitions

Seam welding steelfor the construction industryISO 9001

Add to favorites

Compare this product

Characteristics

- Technique

- seam

- Material

- steel

- Applications

- for the construction industry

- Certifications

- ISO 9001

Description

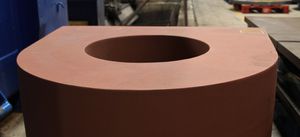

AWS has multiple machines and techniques for beveling edges, weld seam preparation and/or chamfering. We can make V, Y, X or K weld seams at various angles, or chamfer the steel through oxy-fuel or plasma cutting, mechanical grinding or milling. Not only do we have all the machinery to do this, but our experienced and expert staff guarantee work of the highest quality.

All machinery

We offer the following options for the weld seam preparation you require:

Plasma

HPR 400 XD with an infinitely rotating bevel head with a maximum cutting thickness of 50 mm. With one single movement, this machine allows us to cut contours into the product as well as apply various bevels.

Oxy-fuel

Panasonic cutting robot for 3D beveling and chamfering with a maximum cutting length of 200 mm. Various motorized portable cutting machines.

Grinding

Kuhlmeyer long belt grinding machine with a maximum length of 6,000 mm, maximum thickness of 80 mm and range of -45o (minimum) up to +85o (maximum).

Milling cutters

Fully automatic bevel milling machine fitted with automatic feeding. Suitable for materials up to 80 mm and the double-sided beveling using a manipulator.

Other ANCOFERWALDRAM STEELPLATES B.V. products

Plates & Cutting Work

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.