- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Graphite block heat exchanger

- API Schmidt-Bretten, API Heat Transfer group

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

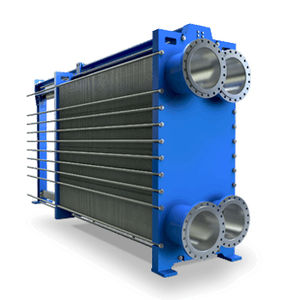

Graphite block heat exchanger Schmidt® SIGMA G-BLOCliquid/liquidgas/liquidgas/gas

Add to favorites

Compare this product

Characteristics

- Type

- graphite block

- Fluid

- liquid/liquid, gas/liquid, gas/gas

- Material

- graphite

- Other characteristics

- corrosion-resistant, high-temperature, custom, gas cooler, for corrosive fluids, condensation, water-cooled

- Applications

- industrial, for the chemical industry, for the petrochemical industry, for the pharmaceutical industry, for viscous products, exhaust gas heat recovery, vaporization, surface

- Operating pressure

Max.: 150 bar

(2,175.57 psi)Min.: 0 bar

(0 psi)- Temperature

Max.: 550 °C

(1,022 °F)Min.: -200 °C

(-328 °F)

Description

Schmidt® SIGMA G-BLOC Graphite Block Heat Exchangers

Our SIGMA G-BLOC graphite block heat exchangers are ideal for use with corrosive materials, offer nearly universal corrosion resistance, and are the highest strength on the market. Made of modular, stacked graphite blocks with mounted PTFE seals between each adjoining block, the blocks are drilled in a specific pattern to optimize heat transfer through the graphite material.

Performance notes.

Compactness

Modular construction

Fast assembly and disassembly; extending the unit is possible

Standardized spare parts

Possibility to use corrosive media on both sides with a protective coating/lining on the shell side

Outstanding corrosion resistance (GT-KELITE/GT-CARB/GT-FLON)

SHOCK PROTECT® shields the blocks from water and steam hammering

STABLE LOAD® limits stress fatigue on the compression springs

STRESS FREE® avoids piping stress on graphite components

Standard design pressure up to 115 psig (8 barg)

Standard design temperature up to 392°F (200°C), or higher design temperatures on request

Heat transfer surface from 3 ft2 to 7,200 ft2 (0.3 m2 to 800 m2)

Customized design for client-specific applications

How it works.

Corrosive medium flows through the axial process holes in the block

Service medium passes through the horizontal holes of the blocks, and flow is properly directed by special baffle cages

The complete unit is maintained under compression with a special STABLE LOAD® springs system

Catalogs

No catalogs are available for this product.

See all of API Schmidt-Bretten, API Heat Transfer group‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other API Schmidt-Bretten, API Heat Transfer group products

Plate

Related Searches

- API - Schmidt-Bretten cooler

- API - Schmidt-Bretten liquid cooler

- API - Schmidt-Bretten heat exchanger

- API - Schmidt-Bretten water cooler

- API - Schmidt-Bretten air cooler

- API - Schmidt-Bretten liquid/liquid heat exchanger

- API - Schmidt-Bretten industrial cooler

- API - Schmidt-Bretten plate heat exchanger

- Compact chiller

- API - Schmidt-Bretten tubular heat exchanger

- API - Schmidt-Bretten stainless steel cooler

- API - Schmidt-Bretten stainless steel heat exchanger

- API - Schmidt-Bretten gas/liquid heat exchanger

- Air-cooled recirculation chiller

- API - Schmidt-Bretten oil cooler

- API - Schmidt-Bretten industrial heat exchanger

- API - Schmidt-Bretten compact heat exchanger

- Process water cooler

- API - Schmidt-Bretten copper heat exchanger

- Water-cooled cooling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.