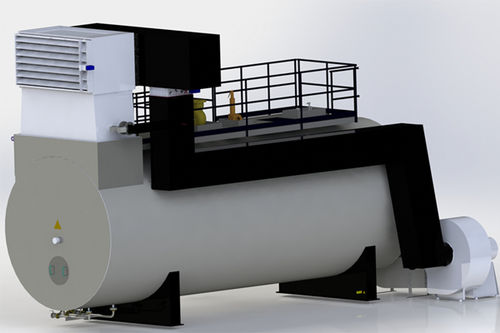

Energy heat recovery system R-Ecofor boiler

Add to favorites

Compare this product

Characteristics

- Options

- energy, for boiler

Description

Energy saving and efficiency are key factors for modern industry. One of the most significant energy users in a typical production facility is the boiler and, recognising this, Babcock Wanson offers the R-ECO solution, which provides improvements in boiler efficiency of up to 98%*. The R-ECO is a combination of two technologies:

Combustion air pre-heating: This technology on its own increases the overall boiler but it can also increase the NOx emission.

Flue Gas Recirculation (FGR): FGR helps reduce the formation of NOx emissions in the flue gas to ensure compliance with environmental regulations.

Principle of operation: Exhaust Gas Combustion Air Preheating Economiser

The benefits of “R-ECO” installation are most apparent where there is greater than 90% condensate return. As returning condensate is already at high temperature this makes it unsuitable for use with classic feedwater economisers. Other operating conditions required for successful R-ECO operation are flue gas inlet temperature above 130 ° C, flue gas temperature output ≈ 100 ° C, and Natural Gas fuel.

Construction: Aluminium Exchanger Plate

Casing: Galvanized steel

Operating Conditions

No other heat recovery sink than combustion air (e.g. in the case of condensate return ≥90%)

Exhaust Gas Inlet Temperature ≥ 130 ° C

Exhaust Gas Outlet Temperature ≈ 70 °

Fuel – Natural Gas

For a boiler feed water temperature ≥ 110 ° C an approximate efficiency gain of 2.5%*

For a boiler feed water temperature ≥ 105 ° C an approximate efficiency gain of 3%*

Catalogs

BWR FIRETUBE STEAM BOILER

2 Pages

Related Searches

- Gas burner

- Hot water boiler

- Steam boiler

- Gas boiler

- Natural gas burner

- Steam generator

- Indirectly fired burner

- Electric steam generator

- Smoke tube boiler

- Electric boiler

- Horizontal boiler

- Fuel oil burner

- Industrial boiler

- Low-emission burner

- Fuel oil boiler

- Three-pass boiler

- Boiler burner

- Monobloc burner

- Natural gas boiler

- Vertical boiler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.