- Environment - Health - Safety

- Waste Treatment

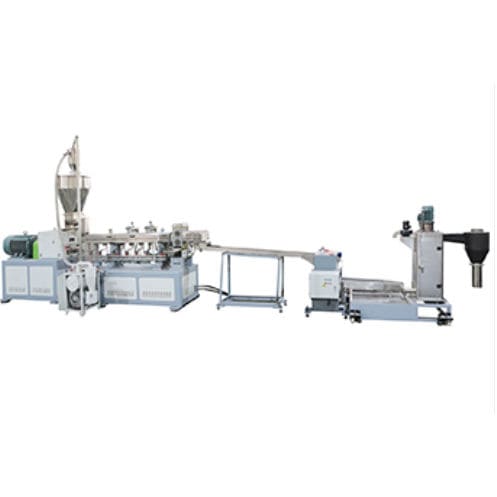

- PET recycling unit

- Chengdu PURUI Polymer Engineering Company

PET recycling unit TSSK95with pelletizing

Add to favorites

Compare this product

Characteristics

- Applications

- PET

- Functions

- with pelletizing

- Productivity

Max.: 1,000 kg/h

(2,205 lb/h)Min.: 800 kg/h

(1,764 lb/h)

Description

Color:Blue, silver or customization

Features:Good screw elements construction and high torque gearbox.

High Torque Corotating Twin Screw Extruder

Parrallel corotating twin screw extruders have excellent mixing performance, good self-cleaning performance and flexible modular configuration characteristics which make them suitable for processing different types of material.

1. Filling modification

CaCo3

Talcum powder

BaSO4

TiO2

Ceramic powder

Wood flour/plant fiber

Other inorganic filler

2. Reinforce Modification

Short glass fiber

Long glass fiber

Carbon fiber

Other whisker

3. Preparation of master batch

Carbon black master-batch

Color master-batch

Flame-retardant master-batch

Degradation master-batch

Degradation master-Batch

Other special functions master-batch

4. Blending modification

Thermoplastic material/Elastomer

Polymer alloys

5. Cable material

PVC cable material

Zero halogen cable material

PE TR-XLPE,NDH

PE-Cross-Linking cable material

Special cable material

6. PET flakes recycling

PET flakes will be mixed and dried with the double disc, with the help of vaccum degassing system during extrusion make sure the IV drops little, IV,0.03. Thanks to the underwater strand pelletizing system and PLC control, it can be automatically control.

Catalogs

No catalogs are available for this product.

See all of Chengdu PURUI Polymer Engineering Company‘s catalogsOther Chengdu PURUI Polymer Engineering Company products

TSSK Co-rotating twin screw extruder for compoundi

Related Searches

- Pelletizer

- Single-shaft shredding machine

- Recycling plant

- Plastic shredding machine

- Plastic pelletizer

- Waste granulator

- Plastic recycling plant

- Compact pelletizer

- Vertical classifier

- Pelletizer for the plastics industry

- Recycling line with pelletizing

- PET recycling line

- Classifier for the plastics industry

- PE recycling line

- HDPE recycling line

- PP pelletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.