- Environment - Health - Safety

- Waste Treatment

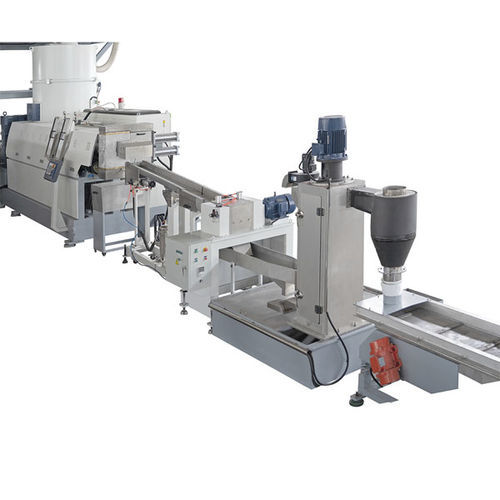

- PET recycling unit

- Chengdu PURUI Polymer Engineering Company

PET recycling unit Ml180with pelletizing

Add to favorites

Compare this product

Characteristics

- Applications

- PET

- Functions

- with pelletizing

- Productivity

Max.: 1,200 kg/h

(2,646 lb/h)Min.: 800 kg/h

(1,764 lb/h)

Description

Color:Blue, silver or customization

It can recycle the most of the soft plastics and some rigid plastics. The soft material contains wholes rolls and crushed PET fibers and films, PET fabrics, LLDPE, LDPE,HDPE,PP,BOPP,CPP from post industrial or post consumer.

Considering the materials characteristics, for some post industrial material we may prefer the single stages pelletizing system. For example the the BOPP films, PET fibers from water jet weaving selvedges, POY discards and DTY discards etc. Considering the regrind pellets will be used for making the new films or fibers, we improve the filtering system. Finally we add two filters on the single screw. In the middel we add one melt pump to increase melt pressure ensure the melted raw material get into the second filter for fine filtering. It will not only increase the pellets quality but also increase the pellets quality.

Apart from the filtering system, we make some improvement on the cutter compactor to add one dehumifying system, it will largely decrease the moisture content of the raw materials.

Finally we will have the under water strand pelletizing to make the strand easy to feed into the pelletizer. It will save the manual work comparing the dry strand pelletizing.

We have been in the plastic recycling machine for more than 15 years. Exporting to more than 70 countries, with good after sale service and reputation. We will continue to serve our customers and offer the best quality machines.

Catalogs

No catalogs are available for this product.

See all of Chengdu PURUI Polymer Engineering Company‘s catalogsOther Chengdu PURUI Polymer Engineering Company products

PURUI ML type pelletizing machines

Related Searches

- Pelletizer

- Single-shaft shredding machine

- Recycling plant

- Plastic shredding machine

- Plastic pelletizer

- Waste granulator

- Plastic recycling plant

- Compact pelletizer

- Vertical classifier

- Pelletizer for the plastics industry

- Recycling line with pelletizing

- PET recycling line

- Classifier for the plastics industry

- PE recycling line

- HDPE recycling line

- PP pelletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.