- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

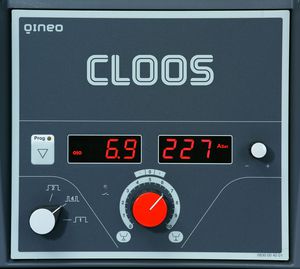

Spot welding power supply QINEO TRONIC 350MIG-MAGautomatedwith 4-roll wire feeder

Add to favorites

Compare this product

Characteristics

- Technique

- spot, MIG-MAG

- Other characteristics

- automated, with 4-roll wire feeder, inverter, with cooling

- Intensity

Max.: 350 A

Min.: 40 A

Description

350 A weld current

Inverter power source

Separate wire drive unit (4 rollers)

Gas or water cooled

Freely configurable options

Quality through precision: Synergy mode, simple operation and job memory in combination with the proven Control Weld und Rapid Weld processes: These characteristics enable excellent welding results to be achieved with the QINEO TRONIC welding power source. Further advantages of the QINEO TRONIC are its small design, free configuration capability and high efficiency. The QINEO TRONIC offers an excellent price/performance ratio for manual and automated welding.

Applications

System/container construction

Equipment manufacturing

Automotive industry

Industrie

Mechanical engineering/steel c

Pipeline construction

Shipbuilding

Special purpose vehicles/const

Base materials

Aluminium

Structural steel

CrNi steel

Standard equipment

Temperature-controlled fan

Synergic operation

Super 4 cycle operation

Stand-by operation

Spot welding

Manual operation

Liftstart

Characteristic curve compensat

Characteristic curve preselect

Burnback automatic

Wire threading

Digital display

Clean Start

CLOOS SZ connection

4 cycle operation

2 cycle operation

Catalogs

No catalogs are available for this product.

See all of CLOOS‘s catalogsRelated Searches

- Industrial robot

- Welder

- Articulated robot

- Arc welder

- 6-axis robot

- Mobile welder

- Handling robot

- MIG-MAG welder

- Three-phase welder

- SMAW welder

- Arc welding torch

- Robotic cell

- Welding robot

- Welding generator

- MIG-MAG welding torch

- Air-cooled welding torch

- Water-cooled welding torch

- Arc welding generator

- Robotic handling cell

- Manual welding torch

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.