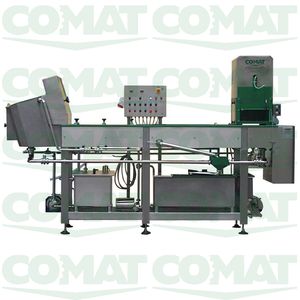

Stretching line M42BS

Add to favorites

Compare this product

Description

According processing and technological requirements, stretching area is designed with single or double vat; and with double couple of dipping arms.

Cheese mass rightly cut by paste cutter assembled downstream machine and feed by elevator with an auger with a diameter of 300 mm is treated by two counter rotary augers which proceed also to a pre stretching treatment before final stretching treatment, done by two stretching area where are installed couple of cheese vat for anyone.

During the process it is possible to control visually the productive cycle at each moment.

Machine body designed with double jackets to waste no humidity. Complete of hot water preparation system with water diffusers into cooking and stretching area. Ability for recycling of processing water; and complete or system for recovering and recirculation of stretching water (under customer and technological requirements). Fat water is taken away through waste pipes and movable pipes which allow to regulate the level of the liquid into the vat and it is recovered in a vat connected to the sanitary recovery pump which evacuate it.

Parts in contact with food are coated in non stick Teflon.

Adjustable speed for any processing function (on request machine can be completed by inverter if not include in model).

Control board in SS304 box IP65.

Catalogs

No catalogs are available for this product.

See all of Comat‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.