- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

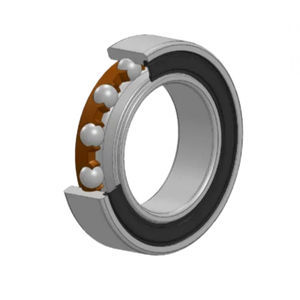

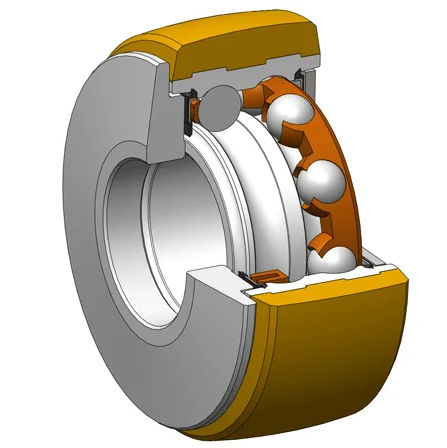

Angular-contact bearing single-rowsteelstainless steel

Add to favorites

Compare this product

Characteristics

- Configuration

- angular-contact, single-row

- Material

- steel, stainless steel, plastic, ceramic, brass

- Applications

- for planetary gearboxes

- Other characteristics

- custom

- Inside diameter

10 mm

(0.39 in)- Outside diameter

800 mm

(31.5 in)

Description

Angular contact bearings have similar construction to deep groove bearings except for the specific track geometry to withstand combined radial and axial loads.

General Features

In the single-row version they must always be coupled with another opposing bearing, usually the same, but for specific cases also with different size and contact angle.

As the contact angle increases, the axial load bearing capacity also increases.

They can be made in many variations:

Shielded with grease (for life);

Open without grease;

Lubricated directly in the machine with oil or grease.

In addition, they can be produced with various types of cages: brass, steel, plastic depending on the requirements of use.

When preloaded, they have the advantage of offering high stiffness. They can withstand very high rotational speeds depending on the contact angle.

Depending on technical requirements, they can have special coatings, e.g., chrome, phosphating, galvanizing, or black oxide.

Materials

In most cases they are made of typical chromium bearing steel, either full hardening or case hardening. For special application requirements they can be made of stainless steel. In special cases ceramic balls can be adopted.

Main Applications

Textile looms, Planetary gearboxes, machine tools, axles, bottling machines.

Catalogs

No catalogs are available for this product.

See all of CPM S.p.A.‘s catalogsRelated Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Axial rolling bearing

- Single-row bearing

- Deep groove ball bearing

- Double-row bearing

- Slewing bearing

- Precision bearing

- Cylindrical roller rolling bearing

- Ball bearing slewing bearing

- Cage assembly bearing

- Tapered roller bearing

- Angular-contact bearing

- Single-row slewing bearing

- Stainless steel rolling bearing

- Axis cam follower

- External-toothed slewing bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.