- Products

- Catalogs

- News & Trends

- Exhibitions

Sorting system for the automotive industry SPDRtransfer vehicle

Add to favorites

Compare this product

Characteristics

- Application domain

- for the automotive industry

- Other characteristics

- transfer vehicle

Description

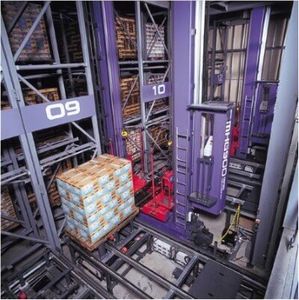

World-First Temporary Storage and Sortation System “SPDR” Developed

In 1957, Daifuku supplied Japan’s first chain conveyors for body transport to an automobile plant. Since then, we have achieved many results in almost all processes of automobile production. For the construction of main assembly lines, in addition to innovative conveyor systems, we have provided various solutions for improving productivity regarding parts handling in the lines and parts supply to the line side. However, systems for the reception and storage of parts from suppliers and timely retrieval according to production schedules often required human labor. To improve such a situation, we developed and launched the SPDR (pronounced spider), a temporary storage and sortation system for parts in December 2014.

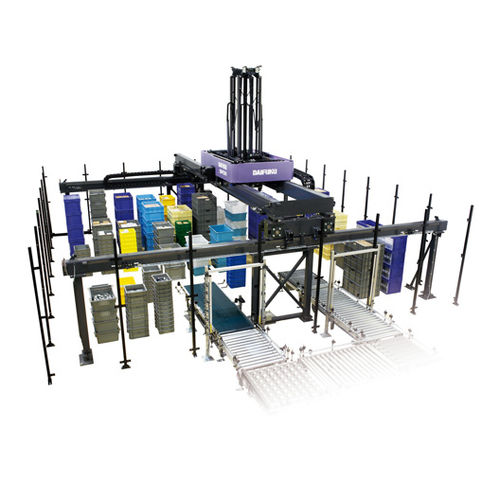

Flexible handling of cases varying in size

The SPDR comprises of the arm, which automatically lowers and raises to grasp cases of parts; a girder, which enables movement in four directions; and the rails and support columns for the girder. The system is able to stack cases directly on the floor of the open area within the support columns. The chuck on the arm is a proprietary technology, and is the world’s first to handle cases of varying sizes. It can grasp cases one by one or in a stack and thus can easily handle cases on lower layers, which facilitates operation, such as picking retrieval and grouping retrieval, to satisfy requirements on the line side.

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Roller rail conveyor

- Sorting machine

- Inclined conveyor

- Drag chain conveyor

- Automatic sorting machine

- Feeding conveyor

- Curved rail conveyor

- Case conveyor

- Carton conveyor

- Conveyor system

- Straight conveyor

- Conveyor for the automotive industry

- Logistic conveyor

- Rail-mounted conveyor

- Accumulation conveyor

- Gravity conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.