- Machine-tools

- Machining Center

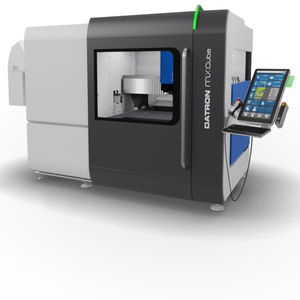

- 3-axis CNC milling machine

- DATRON France SAS

3-axis CNC milling machine M8Cubeverticalfor aluminumfor non-ferrous metals

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Machined material

- for aluminum, for non-ferrous metals, for composites

- Spindle mount

- HSK-E 25

- Number of tool stations

- 24 tools, 30 tools

- Applications

- for the automobile industry, for the aerospace industry, for panels, drilling, for profiles, for 3D-printed metal parts

- Other characteristics

- high-speed, precision, compact, rigid, high-power

- X travel

1,020 mm

(40 in)- Y travel

830 mm

(33 in)- Z travel

245 mm

(10 in)- Rotational speed

60,000 rpm

(376,991 rad.min-1)- Power

Max.: 4 kW

(5.44 hp)Min.: 0.6 kW

(0.82 hp)- Work feed X-axis

22,000 mm/min

(14 in/s)- Work feed Y-axis

22,000 mm/min

(14 in/s)- Work feed Z-axis

22,000 mm/min

(14 in/s)- Weight

1,300 kg

(2,866.01 lb)- Overall length

1,740 mm

(68.5 in)- Overall width

2,340 mm

(92.1 in)- Overall height

1,950 mm

(76.8 in)

Description

High dynamics through optimized controls with a focus on acceleration and stiffness designed mechanical design.

Rigid, low-vibration design of the machine for excellent surface quality when machining.

Your benefits at a glance:

The M8Cube is one of the latest additions to our wide range of compact high-speed CNC machines for any milling requirement. New controls, new features, ergonomic working environment and low operating cost - let our range of accessories and software features prove the difference.

Very large working area while keeping a small footprint

Affordably priced with extremely low operating cost

Short set-up times

You have new opportunities in milling, drilling and engraving. The M8Cube was engineered to process high-tech materials with small tools (Ø 0.1 mm to 20 mm)

The M8Cube is the top choice for the efficient machining of housings, profiles and panels made of aluminium and other nonferrous metals or cmposites. M8Cube stands for state-of-the-art milling technology "Made in Germany" for your production success.

Technologies

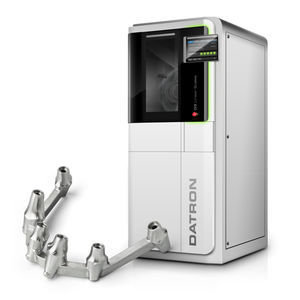

The efficiency of CNC production is decisively determined by the accessories. Therefore DATRON develops powerful accessories for effective and thus profitable work.

DATRON machine software

A special highlight is the completely new developed (r)evolutionary DATRON next machine control. Some special features are smartphone-like operation via a 24" touch screen, automatic tool management, camera-assisted setup of zero points, very dynamic control for fast machining and perfect surfaces.

VIDEO

Catalogs

DATRON_CNC-Machine_Catalogue

64 Pages

DATRON Accessories-Catalogue

102 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Applications CNC milling machine

- Bridge CNC milling machine

- Precision CNC milling machine

- 5-axis CNC milling machine

- High-precision CNC milling machine

- Aluminum CNC milling machine

- High-performance CNC milling machine

- Rigid CNC milling machine

- Compact CNC milling machine

- Composite CNC milling machine

- Horizontal CNC milling machine

- CNC milling machine for the automobile industry

- 24 tools CNC milling machine

- High-speed CNC milling machine

- 60 tools CNC milling machine

- CNC milling machine for the aerospace industry

- Panel CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.