- Products

- Catalogs

- News & Trends

- Exhibitions

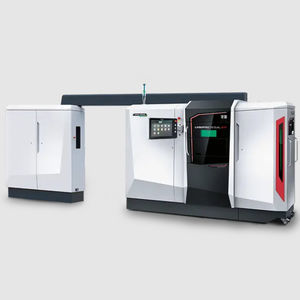

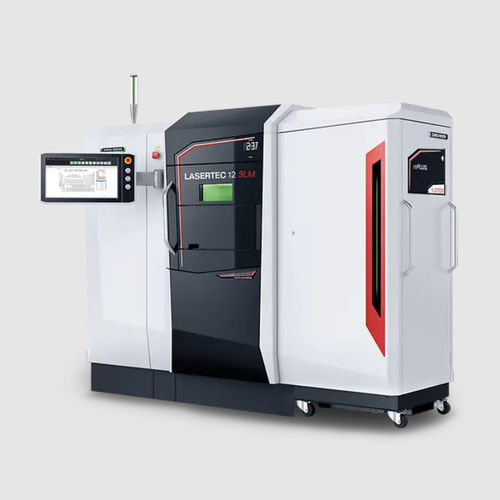

Metal additive manufacturing machine LASERTEC 12 SLMSelective Laser Melting

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- metal

- Technology

- Selective Laser Melting

- X travel

125 mm

(4.92 in)- Y travel

125 mm

(4.92 in)- Z travel

200 mm

(7.87 in)

Description

Additive Manufacturing by selective laser melting (SLM) in powder bed

Highly complex components with function integration

Internal conformal cooling channels

Weight optimisation due to lattice and honeycomb structures as well as topology-optimised components

Simultaneous build-up of different designs

Functional prototypes made of series materials

High precision building of 3D parts with a focus diameter of only 35 µm

Application-specific fibre laser sources from 200 W as standard to 400 W optional

Optimised shield gas volume flow for highest component quality with minimum Argon consumption

Open system: Individual adjustment of all machine settings and process parameters as well as unrestricted selection of the material supplier

End-to-end competence with integral process understanding from drawing to finished part: DMG MORI Process Chains for pre- and post-processing of additively built parts

rePLUG – The powder module for fast material change

Automated powder handling: Integrated powder-recycling for maximum efficiency and highest work-safety due to closed material cycle

One material per rePLUG – Any expansion of the material range due to modular changing system

Contamination-free change between different materials in <2 hours

High process autonomy due to powerful duo filter system (filter change without process interruption) as well as large powder reservoir (no manual refilling required in the process)

Optional: rePLUG RESEARCH The additional powder module, especially developed for the material and process parameter development on the series system

VIDEO

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.