- Machine-tools

- Machining Center

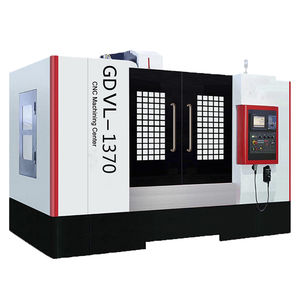

- 3-axis machining center

- Dongguan Gooda Machinery Manufacturing Co., Ltd.

Horizontal CNC machining center GDHM-80GNC3-axisrotating tablefixed-bed

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- horizontal

- Structure

- rotating table, fixed-bed

- Machined material

- for aluminum

- Spindle mount

- BT 40

- Number of tool stations

- 24 tools

- Applications

- drilling

- Other characteristics

- milling, high-speed, high-precision

- X travel

1,300 mm

(51 in)- Y travel

1,000 mm

(39 in)- Z travel

1,050 mm

(41 in)- Rotational speed

6,000 rpm

(37,699 rad.min-1)- Power

15 kW, 18.5 kW

(20.39 hp, 25.15 hp)- Table load capacity

3,000 kg

(6,614 lb)- Tool weight (max)

7 kg

(15.4 lb)- Positioning accuracy

0.01 mm

(0 in)- Repeatability

0.006 mm

(0 in)- Tool-changing time

1.8 s

- Weight

22,500 kg

(49,604.01 lb)- Overall length

5,300 mm

(208.7 in)- Overall width

4,200 mm

(165.4 in)- Overall height

3,580 mm

(140.9 in)

Description

GDHM-80G adopt HT300 strength inoculated cast iron has been completely eliminated by secondary annealing, vibration aging and sufficient aging treatment

Can automatically exchange tools, can be clamping four sides of milling, drilling, reaming, boring.

The internal stress produced by manufacturing stress and rough machining ensures good rigidity, high strength and stable structure of the casting

Tapping, end face, boring step hole and other processes;

Long-term high accuracy and stability.

GDHM-80G GooDa CNC Horizontal Machining Center

The Features

· One clamping can realize complex processing in four sides and multiple processes, with strong processing capacity, wide application range and high price

"Bed casting is made of resin sand molding,HT300 strength inoculated cast iron

Than high

· The main castings of the bed body (base, workbench, column, saddle, headstock, etc.) are made of resin sand

· It is suitable for multi-variety processing of complex box parts with holes and high coaxiality requirements in the process of processing

The Advantages

· Design the structure of the one-piece bed, use the finite element analysis to optimize the reasonable reinforcement arrangement and match the M-shape

· Large inertia feeding servo motor, high rigidity ball screw and guide rail, good stability and high precision.

· The reinforcement makes the column and the bed integrated, the performance indexes of each component are guaranteed, and the bed has high rigidity.

Other Dongguan Gooda Machinery Manufacturing Co., Ltd. products

CNC Machining Center Machine

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Gantry CNC machining center

- Drilling machine

- Milling CNC machining center

- Cutting CNC machining center

- Column type CNC machining center

- Applications CNC milling machine

- Aluminum CNC machining center

- BT 40 CNC machining center

- Bridge CNC milling machine

- Horizontal CNC machining center

- Drilling CNC machining center

- Precision CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.