CNC turning machine VL 6vertical3-axis12 tools

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- vertical

- Number of axes

- 3-axis

- Number of tool stations

- 12 tools

- Applications

- for heavy-duty machining, for large workpieces

- Other characteristics

- high-productivity, spindle

- Diameter

400 mm

(15.75 in)- Spindle speed

3,100 rpm

(19,477.874 rad.min-1)- Part diameter

300 mm

(12 in)- Maximum part length

250 mm

(10 in)- Axe X

900 mm

(35 in)- Axe Z

495 mm

(19 in)- Rapids on X

60,000 mm/min

(39 in/s)- Rapids on Z

30,000 mm/min

(20 in/s)- Nominal power

28 kW, 39 kW

(38.1 hp, 53 hp)- Maximum torque

340 Nm, 460 Nm

(251 ft.lb, 339 ft.lb)

Description

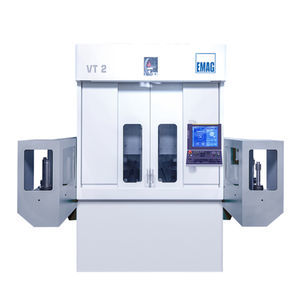

The VL 6 vertical lathe machine offers the same features as the newest EMAG modular designs in a vertical turning machine for larger, heavy workpieces. Equipped with a standard workpiece conveyor and pick-up spindle, the cnc lathe machine loads itself with minimized chip-to-chip times. With a machine base made of the polymer concrete MINERALIT®, a material well-known for its excellent damping quality, it offers extended tool life and outstanding surface finishes.

Vertical Lathe with Pick-Up Automation for Efficient Machining

With the goal to develop a system of modular machines ideal for use in the manufacturing of medium and large batch runs, one common feature of all the new EMAG modular machines is the basic, compact design. Their small footprint means reduced floor space costs and flexibility in machine layout (for example, Chaku Chaku or closed loop arrangement). Every VL vertical lathe features an integrated O-automation system for transporting workpieces on its left-hand side. When combined with the self-loading pick-up spindles, this automation concept ensures short cycle times and high productivity.

To accommodate machine operators, all the service units are easily within reach, with various units (electrics, hydraulics, cooling system, cooling lubricant and central lubrication system) accessible at any time so that the vertical lathes can be maintained with ease. With low maintenance costs due to the use of standardized components, excellent accessibility, reduced floor space costs, integrated automation and short cycle/idle times bringing the cost per unit to a minimum, the goal of EMAG vertical lathes is clear: cost saving without compromising quality.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.