- Products

- Catalogs

- News & Trends

- Exhibitions

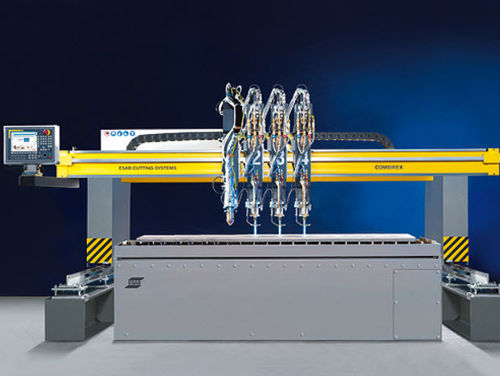

Oxy-fuel cutting machine COMBIREX DX seriesplasmafor aluminumfor stainless steel

Add to favorites

Compare this product

Characteristics

- Technology

- oxy-fuel, plasma

- Material

- for aluminum, for stainless steel

- Control type

- CNC

- Associated function

- marking

- Configuration

- gantry type, 3-axis

- Other characteristics

- automatic, high-performance, combined

- Y travel

Max.: 3,000 mm

(118 in)Min.: 1,500 mm

(59 in)- Cutting speed

Max.: 25,000 mm/min

(16.404 in/s)Min.: 50 mm/min

(0.033 in/s)

Description

The Combirex DX offers large gantry design and performance in a compact package. The rugged gantry features all-steel construction with machined mating surfaces for stiffness and accuracy. Heavy duty weldments support triple machined T-rails to provide a sturdy, stable foundation. Featuring a precision linear rail Y-axis guiding system, precision three-axis rack-and-pinion drives, digital AC drives and AC brushless motors, this machine delivers the cutting performance you would expect from much more expensive gantries.

Plasma stations

The Combirex DX can be equipped with air plasma systems up 120 amps or ESAB’s iSeries Plasma System, which allows the machine to cut and mark with the same plasma torch. The iSeries system is available on the Combirex DX in 100, 200, 300 or 400 Amp configurations.

Plasma bevelling

The Combirex DX can be equipped with the optional DMX Automated Plasma Beveller. The compact plasma bevel system uses compound motion and ESAB’s SmartBevel Technology to deliver high productivity with reliable beveling.

Oxy-Fuel torch stations

The Combirex DX may be equipped with up to 4 oxy-fuel cutting stations. The stations feature heavy duty motorized lifters with capacitive height control and pilot flame torch ignitors. An electronic proportional valve gas control sets high/low preheat pressures, cutting oxygen pressure, and pierce ramp automatically through the built-in process database.

Catalogs

Welding and Cutting Catalogue

92 Pages

Welding Filler Metal Handbook

556 Pages

Related Searches

- ESAB cutting machine

- ESAB metal cutting machine

- ESAB CNC cutting machine

- Automatic cutting system

- High-speed cutting system

- Tube cut-off machine

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- High-performance cutting system

- Steel cutting system

- Compact cutting system

- Bridge cutting system

- ESAB plasma cutting machine

- Marking cutting system

- Profile cutting center

- 3-axis cutting system

- Gantry type cutting system

- Heavy-duty cutting system

- Beveling cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.