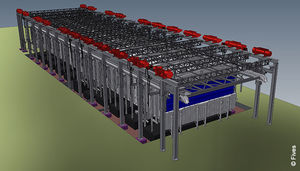

Processing line NEOKOIL® CAPL

Add to favorites

Compare this product

Description

NeoKoil® cold annealing and pickling lines (CAPL) utilizing proprietary technologies for stainless steel applications that require a high level of precision and better surface quality:

DMS 20Hi cold rolling mills - Reducing strip thickness while guaranteeing strip surface quality

Entry and exit sections – Careful handling ensures minimal waste and optimal product quality

NeoKlean® system – Environmentally friendly and cost-effective degreasing

Stein Direct Fired Furnace – High quality and uniform heating with AdvanTek® burners

NeoPik™ system – Utilizing Scale-X™ for effective oxide removal

2Hi skin-pass mill – High-quality finish to reach the 2B standard

SCALE-X™ - our proprietary solution for oxide removal utilizes an aqueous salt solution to replace electrolytic sodium sulfate (ESS) in pickling. Scale-X™ is compatible with existing downstream pickling processes and allows enhanced flexibility for optimized process performance.

Cold rolled steel is typically used in applications that require a high level of precision and better surface quality. Fives has designed NeoKoil® cold annealing and pickling lines (CAPL) utilizing proprietary technologies to ensure optimum product quality and efficiency. The latest reference includes a new CAPL with a production capacity of 500,000 tons per year to produce 200 and 300 series stainless steel products for Foshan Chengde New Material Co., China. Watch the video

Catalogs

No catalogs are available for this product.

See all of Fives DMS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.