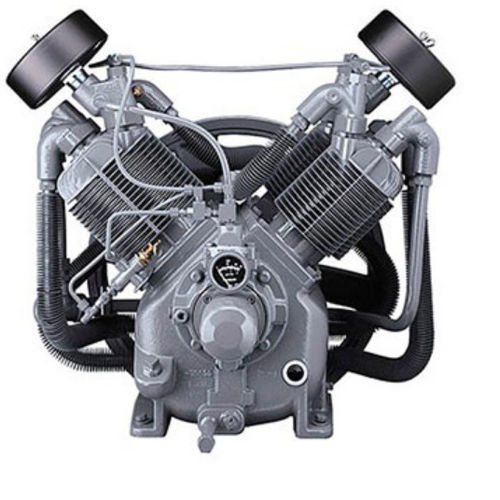

Piston compressor PL seriesairelectrically-poweredstationary

Add to favorites

Compare this product

Characteristics

- Technology

- piston

- Type

- air

- Power source

- electrically-powered

- Portability

- stationary

- Lubrication

- lubricated

- Application domain

- industrial

- Applications

- engine, cylinder

- Other characteristics

- air-cooled, water-cooled, two-stage, duplex

- Tank volume

Max.: 250 l

(66 gal)Min.: 80 l

(21.1 gal)- Pressure

125 psi, 175 psi, 250 psi

(1,812.97 psi, 2,538.16 psi)- Flow

Max.: 119.83 ft³/min

(7,190.07 m³/min)Min.: 10.9 ft³/min

(0.31 m³/min)- Power

Max.: 35 ch

(35 hp)Min.: 3 ch

(3 hp)- Length

Max.: 89 in

Min.: 38 in

- Width

Max.: 34 mm

(1 in)Min.: 23 mm

(1 in)- Height

Max.: 57 mm

(2 in)Min.: 30 mm

(1 in)- Weight

Max.: 802 kg

(1,768.1 lb)Min.: 509 kg

(1,122.2 lb)

Description

The PL-Series compressor has been designed to operate in extreme duty applications and is a pressure-lubricated alternative to the R-Series unit. Because the PL-Series can operate up to 250 psig in remote locations or in off-level operations, it is a true industrial use compressor. The PL-Series features domed pistons, integral cylinder head, disc valves and an oil pump that provides lubricant to all crucial parts of the compressor.

Specifications and Features

Tank or Base Mounted, Simplex, Duplex and Engine Driven Models

Two-Stage pressure lubricated pumps

Loadless auto stop/start

Pro-rated 5-year pump warranty and 1-year package warranty

Factory filled with AEON lubricant

Key Features

Oil Pressure Gauge mounted on the front of the compressor for an excellent view and easy pressure monitoring

Tapered Roller Bearings insure long operating life of the crankshaft

Positive Displacement Oil Pump provides lubricant to all critical areas of the compressor pump that require lubrication

Crankshaft and connecting rod bearings are pressure lubricated for extended life

An external spin on oil filter and an internal oil inlet screen protect internal components from damaging debris

Hydraulic unloader with factory-set pilot valve provides easy, loadless start and low pressure protection for unattended operation

Industrial class bearings

Optional Equipment: Magnetic Starter, Air-Cooled or Water-Cooled Aftercooler, Automatic Tank Drain (Pneumatic), Vibration Isolators, Low

Catalogs

R & PL Series Brochure

12 Pages

Related Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Electrically-powered compressor

- Reciprocating compressor

- Oil-injected compressor

- Dry compressor

- Screw compressor

- Compact compressor

- Low-noise compressor

- Cooled compressor

- Tank-mounted compressor

- Multi-stage compressor

- Gas compressor

- Oil-lubricated compressor

- Air-cooled compressor

- High-pressure compressor

- Two-stage compressor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.