- Industrial machines and equipment

- Mixing and Dosing

- Dynamic homogenizer

- GD Process Design, LLC

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Dynamic homogenizer FBF seriescontinuousfor liquidsdairy product

Add to favorites

Compare this product

Characteristics

- Technology

- dynamic

- Batch/continuous

- continuous

- Product type

- for liquids

- Applications

- dairy product

- Other characteristics

- stainless steel, high-pressure, piston, single-stage, variable-speed, two-stage, for high-viscosity materials, multi-stage, clean-in-place (CIP)

- Engine power

30 kW, 37 kW, 45 kW

(40.79 hp, 50.31 hp, 61.18 hp)- Flow

Max.: 120 l/h

(31.70065 us gal/h)Min.: 90 l/h

(23.77548 us gal/h)

Description

• 2nd stage homogenizing valve controlled by a special oil-pneumatic system

• Digital pressure transducers and analogue gauges with 4-20 ma output

• Fixed Capacity (remote stainless steel panel, with soft-starter)

• Variable Capacity (remote stainless steel panel)

• Aseptic Version with “sterility barriers” traced with steam condensate created by an integrated plant

• Pulsation dampeners on product inlet and/or outlet connections, for special aseptic version as well

• Pressure gauge with alarm contacts for the automatic cut-off of the homogenizing pressure, complete with timing device to manage the start/stop of the homogenizing valves

• Automatic homogenization pressure controller

• Abrasive Version

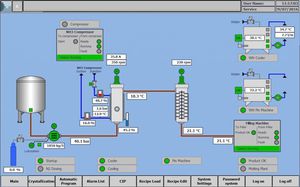

• Automatic Control System

• Aseptic Sterilization System

• Partial Homogenization (Dual Inlet and Blending System)

• MCC Panel

Catalogs

No catalogs are available for this product.

See all of GD Process Design, LLC‘s catalogsOther GD Process Design, LLC products

GD Process Design Edible Oils and Fats

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Agitator for the chemical industry

- Vertical agitator

- Stainless steel homogenizer

- Solid blender

- In-line mixer

- Powder blender

- Horizontal blender

- Solid/liquid homogenizer

- Agitator for the pharmaceutical industry

- Homogenizer for the cosmetics industry

- Homogenizer

- Side-loading agitator

- Compact homogenizer

- Dynamic homogenizer

- Laboratory homogenizer

- Vacuum homogenizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.