- Machine-tools

- Machining Center

- CNC milling-turning center

- GF Machining Solutions

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

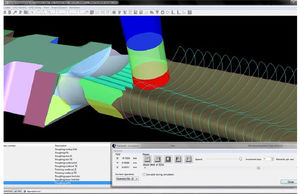

CNC turning-milling center MILL E seriesvertical5-axisprecision

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Type

- vertical

- Number of axes

- 5-axis

- Other characteristics

- precision, high-productivity

- X travel

1,000 mm, 1,380 mm, 1,880 mm

(39 in, 54 in, 74 in)- Y travel

1,150 mm, 1,400 mm

(45 in, 55 in)- Z travel

900 mm, 930 mm

(35 in, 37 in)

Description

Produce efficiently accurate and precise parts with high surface quality to meet the expectations of your customers in the part production and mold and die in general mechanical, aerospace and automotive industries. Count on enduring precision – even over long machining times- thanks to a sturdy portal cast base and hand-scraped key components. Achieve unbeatable productivity and accuracy on this range thanks to this solution's integrated automation and machining dynamics over long milling process.

Five-axis simultaneous mill-turn

Break into new markets with process-secure production of highly demanding parts even milling or tuniring simultaneous application. Tackle both complex and simple applications due to ideal machinine geometry, electronic optimization, dynamic direct drives for round axes, best measuring components and powerful control.

Profit every day from a best ergonomy

Save valuable time devoted to supervising your machining process with this solution's ergonomic design. Whether you are changing tool insert, checking the workpiece surface or measuring workpiece dimensions, this solution's ideal access makes it fast and easy to use in a daily bases.

Increase your workshop's productivity

Expand your productivity, not your shop floor, whit our solutions offering the biggest work area on the smallest footprint. Ramp up your productivity per square meter due to integrated peripherals.

Count on a fulltime efficient productivity

Produce precise five-axis parts throughout the full lifetime of the machine, thank to our week long scraping of the guide rail's supports.

VIDEO

Catalogs

Mikron MILL E 500 U / 700 U

34 Pages

Mikron MILL E 800 / E 1200

24 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- GFMS - GF Machining Solutions CNC milling machine

- GFMS - GF Machining Solutions vertical CNC milling machine

- 3-axis CNC milling machine

- Drilling machine

- GFMS - GF Machining Solutions applications CNC milling machine

- GFMS - GF Machining Solutions precision CNC milling machine

- CNC drilling machine

- Turning-milling machine

- CNC turning-milling center

- 5-axis CNC milling machine

- GFMS - GF Machining Solutions high-precision CNC milling machine

- Vertical drilling machine

- High-performance CNC milling machine

- Rigid CNC milling machine

- Compact CNC milling machine

- CNC milling machine for the mold industry

- 5-axis turning-milling center

- High-productivity CNC milling machine

- CNC milling machine for the automobile industry

- 24 tools CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.